Image Armor is proud to announce that Equipment Zone, located in Franklin Lakes New Jersey, is now a dealer for Image Armor pretreatments for direct to garment printing. Equipment Zone carries a full line of DTG supplies including inks, pretreatments, printers, parts, heat presses and more. Located in Franklin Lakes, […]

DTG

Image Armor is proud to announce that we’ve finally gone to the Land Down Under. We are happy to introduce our newest distributor covering all of Australia, ASTech Solutions based in Sydney. Astech Solutions has been with DTG since it’s inception, providing installation and training services for DTG printers since the “birth” of DTG […]

Image Armor, LLC is proud to announce that American Print Supply of Phoenix, Arizona is distributing the Image Armor line of Pretreatments for direct to garment printing. American Print Supply carries a complete line of screen printing supplies and specializes in DTG printer parts, inks, supplies and service. They […]

Image Armor Pretreatment Solutions Launches in Europe Image Armor is proud to announce that DP Solutions (Renchen, Germany) is now carrying the Image Armor line of pretreatment solutions for direct to garment printers. DP Solutions provides printing solutions for direct printing, metal processing, UV direct printing, textile printing, print & […]

Tips for Printing 100% Polyester Garments with Image Armor LIGHT One of the hottest markets for printing is the sports performance fabrics markets commonly known as 100% polyester garments. For the DTG printer, these are extremely difficult fabrics to print because the nature of the fibers is to “wick” moisture […]

It’s official. Image Armor is going to make its 2014 debut at the Long Beach Imprinted Sportswear Show. Make sure to stop by booth #2255 to see what all the fuss is about! Just look for “Hat Guy” and the Image Armor Girl! In addition, sign up by December 31st, […]

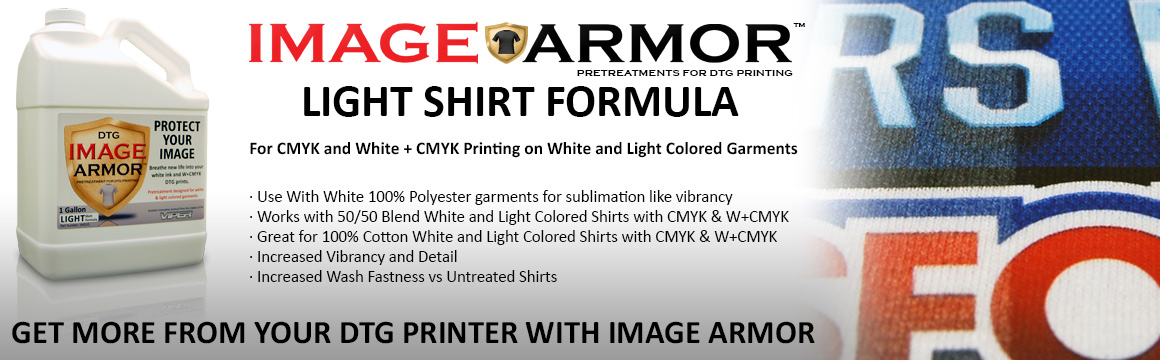

Image Armor is proud to announce the release of the new Image Armor LIGHT Shirt Formula for White and Light Colored garments. The new LIGHT Shirt Formula expands your printing capabilities beyond anything you thought possible with increased vibrancy and wash fastness like you’ve never seen before in DTG printing. […]

The market for DTG printing in the past had been relatively limited to 100% cotton garments. Unfortunately there was not a lot of selection of hooded sweatshirts in anything but a 50/50 blend. Our in-house testing has shown that with our soon to be released Image Armor Light shirt formula, […]

GET FINISHED PRINTS THAT LOOK LIKE HIGH END SCREEN PRINTS WITH A DTG PRINT Traditionally the standard 50/50 shirts has not been a great product to print with the DTG process. Untreated shirts would have very weak, fuzzy, and non-bright images. The pretreatments that were available on the market were […]

15X WASH/DRY CYCLES – 100% COTTON FABRIC TEST PRINT Here’s the 15X washing and drying of our soon to be released Light Shirt Formula. This formula is designed to be applied to white and light colored shirts that are 100% cotton, 50/50 blends and 100% polyester garments.The photo to the […]