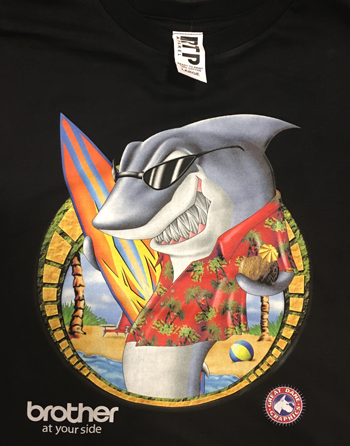

New RTP Apparel Ready To Print Shirts Work Great on Brother GT-381 RTP Apparel is the DTG industry’s most innovative new product in years. No pretreating is required to be successful in the direct to garment printing industry. No mess or guessing how much pretreatment to apply to the T-Shirt. No […]

DTG

New RTP Apparel Prints Incredibly Well on Epson F2000 At the 2016 Ft. Worth Imprinted Sportswear Show we had an opportunity to show off the Image Armor technology being used in the new RTP Apparel shirts. These shirts are engineered for DTG printing.. The RTP Apparel stands for Ready To […]

RTP Apparel Ready To Print Shirts Image Armor is proud to announce our partnership with RTP Apparel which licenses the Image Armor technology for their groundbreaking new T-Shirts. RTP Apparel is the industry’s first DTG engineered t-shirt that requires no pretreatment prior to printing with your direct to garment printer. […]

Printing 100% Polyester Shirts with the Epson F2000 DTG Printer Printing on 100% polyester fabrics has always been problematic. The colors are not vibrant, the image clarity is fuzzy due to bleeding, and the wash durability is not the best. There have not been many options for the Epson F2000 DTG […]

2016 Long Beach NBM Show: Mary Lyn stopped by our booth at the 2016 NBM Long Beach just to let us know she uses our inks and pretreatments. She told the story of shirts she printed for her husband and how well they’ve washed and how she love the Image Armor […]

2016 Long Beach NBM Show: John Hernandez from Old California Printing stopped by our booth at the 2016 NBM Long Beach show and gave us a little history on his DTG experience and how the Image Armor inks and pretreatments helped his Direct to Garment business. Here’s a short testimonial […]

Come to Long Beach and See the Difference! Make sure to stop by our booth at the long Beach NBM show this week, July 14th-16th and see how Image Armor’s LIGHT Shirt Formula pretreatment can change the way you print with your Brother GT3 DTG printer. We will have our […]

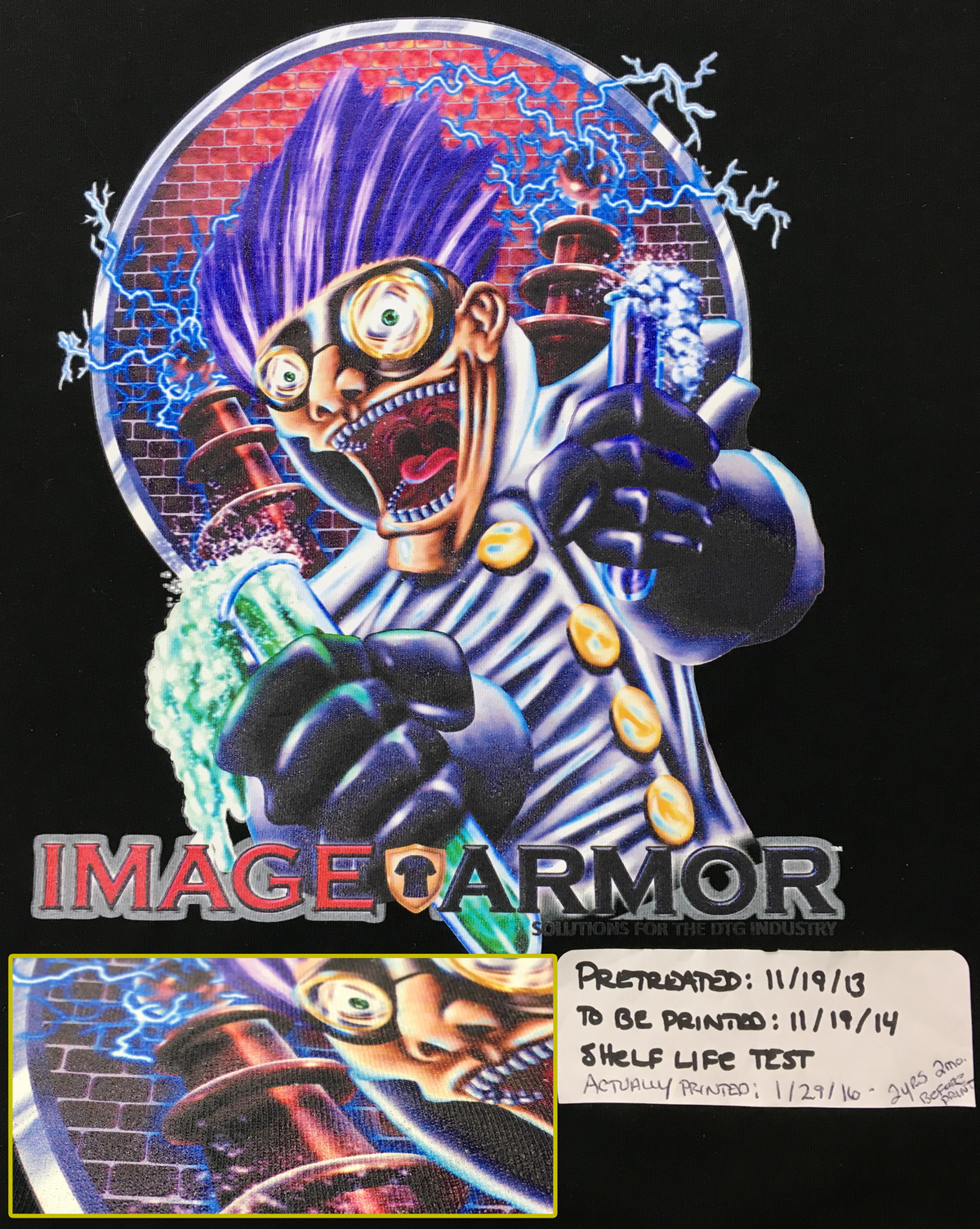

NOTE: This is a re-post of an article we posted in January of 2016. We get a lot of inquires about this, so we thought it prudent to repost this article for everyone’s knowledge base. We often get asked how long can I pretreat a shirt and then leave it […]

JULY 14th-16th, 2016 Mid-summer is coming quickly and so is the Long Beach NBM Printwear show. If you have not been to a show lately, make sure to come and see what’s new – especially in the Image Armor booth. We will be showcasing how Image Armor can definitely change […]

The Nashville Imprinted Sportswear Show is coming up quickly and we wanted to invite you to the show! Visit the Nashville Convention Center May 19th – 21st and come and see why Image Armor is changing the industry. Find out how Image Armor can help your DTG business be more profitable this […]