There were some exciting new developments that were unveiled at the 2019 Printing United (formerly known as SGIA) in Dallas during the October 23rd-25th 2019 show. M&R showcased their newest Direct To Garment printer the Maverick. This new DTG printer had some very unique and new additions that would appear […]

pretreating

[siteorigin_widget class=”WP_Widget_Media_Image”][/siteorigin_widget] Streamlined Pretreatment Production via RFID Now Available In an effort to continually improve the Direct To Garment process i-Group Technologies has always tried to make pretreating easier. The Viper MAXX pretreatment machine is now also RFID capable with the addition of a simple and inexpensive RFID reader that […]

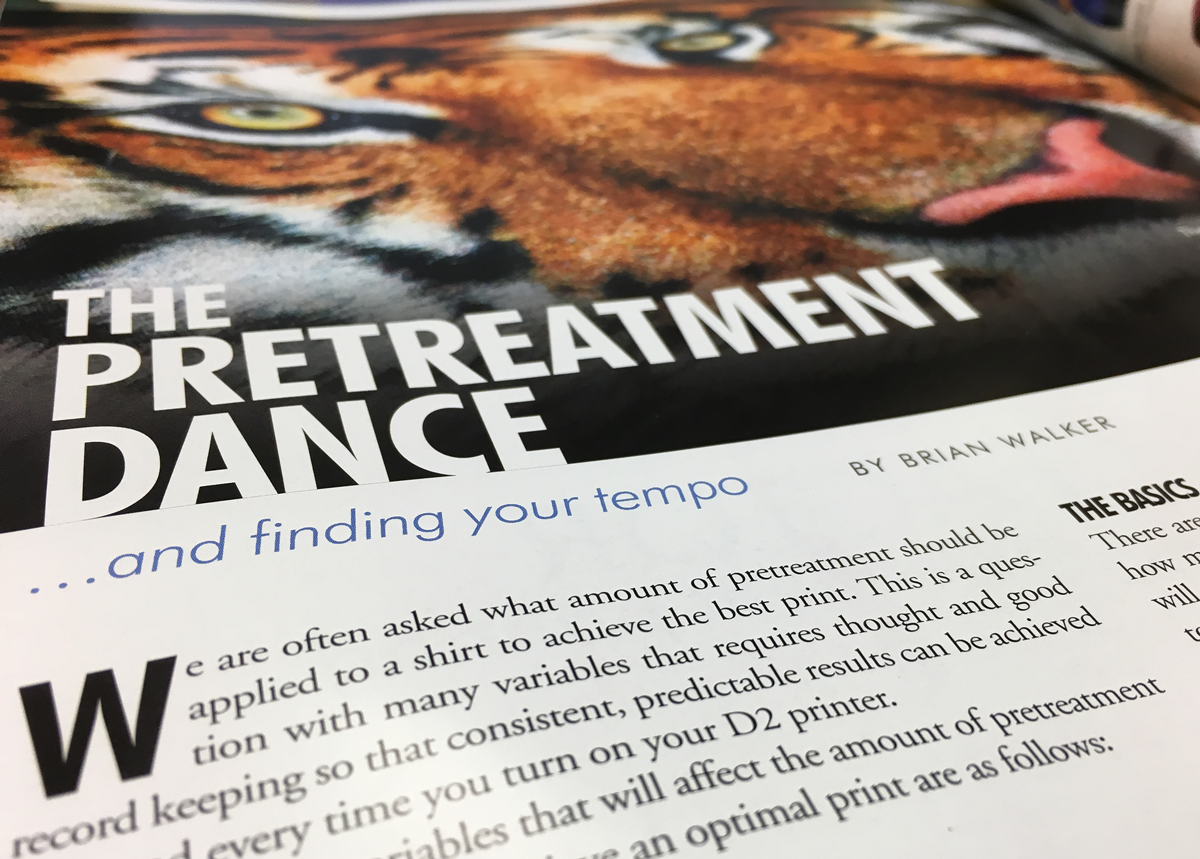

The Pretreatment Dance – What is the Right Amount of DTG Pretreatment? A very often asked question in Direct To Garment printing is “How much pretreatment do I need to apply to the shirt?”. For the new DTG printer (and those who’ve printed for a while) this is a very […]

Image Armor is proud to announce in our effort to be as environmentally conscious as possible that all of our pretreatments have recently passed a battery of tests and have been found to be compliant with the following: CPSIA Compliant – Consumer Product Safety Improvement Act California Prop65 Complinat 100% […]

Image Armor is proud to announce that Equipment Zone, located in Franklin Lakes New Jersey, is now a dealer for Image Armor pretreatments for direct to garment printing. Equipment Zone carries a full line of DTG supplies including inks, pretreatments, printers, parts, heat presses and more. Located in Franklin Lakes, […]