On the Second Business Day of Christmas Image Armor Gave to…….. John from Cleveland, Ohio. Today’s Selectee was John from Cleveland, Ohio. John, though shy and didn’t want to have his information posted, will be receiving a complete Image Armor Ink and Pretreatment change over kit containing a Liter of each our E-Series […]

DTG

It’s December 9th and the 1st Business Day of Christmas in our Christmas Give-Away! Today’s Selectee was Kenan Canales of Excelsior! Digital Apparel in N. Kansas City Missouri. Kenan will be receiving a complete Image Armor Ink and Pretreatment change over kit containing a Liter of each our E-Series DTG inks […]

It’s the 12 Business Days of Christmas Give Away! Image Armor is going to be giving away 12 complete change over kits of our popular E-SERIES inks starting December 9th, 2015! That’s right – giving away complete ink change over kits…. It’s our way of saying Merry Christmas to twelve […]

We wanted to show everyone how important it is to ensure that your DTG ink is properly cured. Figure 1 shows two different shirts with the same image printed. The garment is a 100% black polyester fabric with the Image Armor E-SERIES inks. This picture is after just one wash and […]

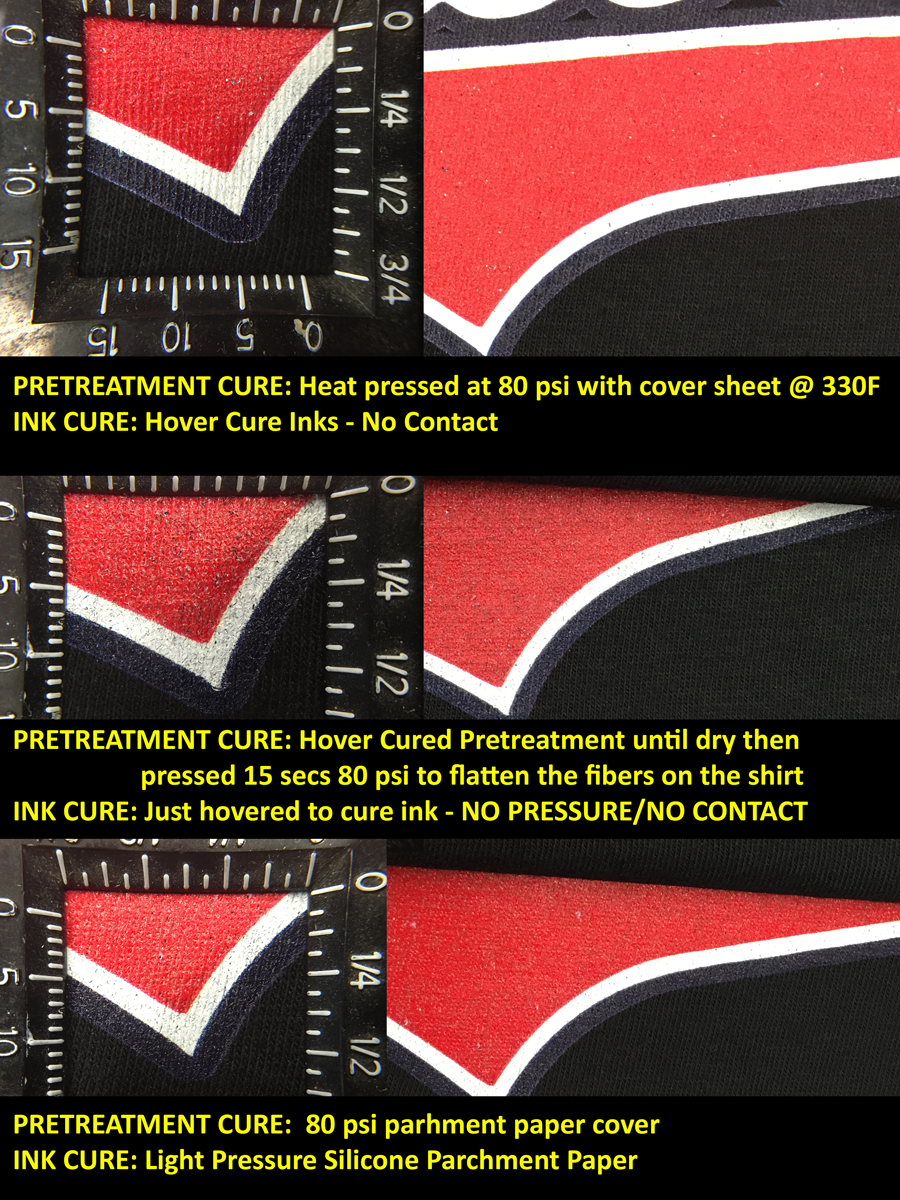

TIP #1: PRETREATING AND CURING THE PRETREATMENT FOR 100% BLACK POLYESTER PRINTING You will typically need MORE pretreatment than a standard 100% cotton garment. Try starting your testing with 30-40 grams of ULTRA pretreatment. This means the shirt is going to be WET! Try Hover Curing…… this will require NO […]

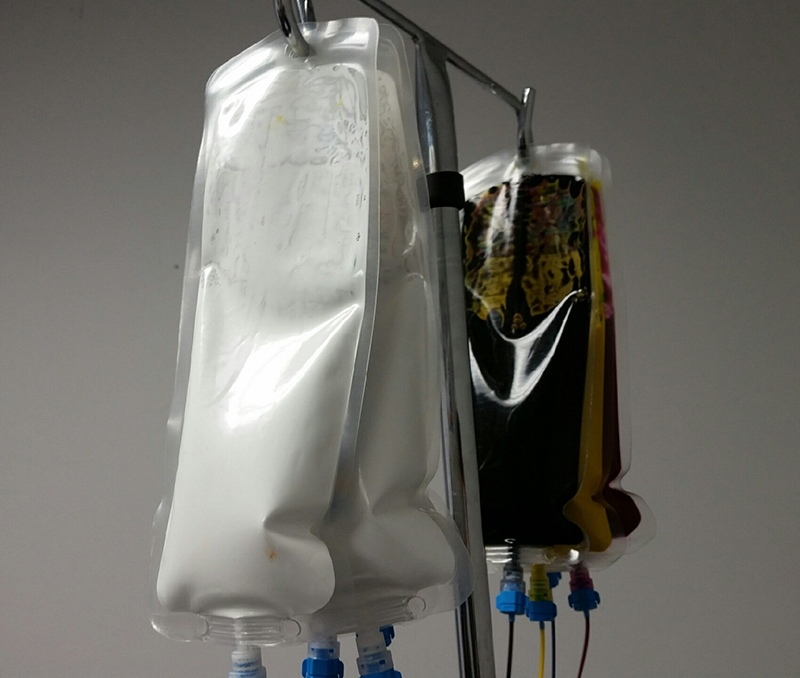

Many DTG printers today are utilizing what can easily be called the DTG IV Bag Ink System. That is because if you have ever been to a hospital and been hooked up to one, you know it looks exactly like an intravenous drip system used to administer drugs into a […]

It’s fun for us to do the trade shows circuit with the Image Armor products. We often get DTG printers who stop by our booth and have never tried any of the Image Armor pretreatments. When they see what our pretreatments are capable of letting them achieve, they start to get excited. […]

Image Armor announces that Capricorn of Piekoszów, Poland is the newest Image Armor dealer. Capricorn, located in Southern Poland, is a full service DTG printer and consumable supplier and carries a complete line of the Image Armor E-SERIES inks and pretreatment solutions. For DTG printers in Poland interested in learning more about […]

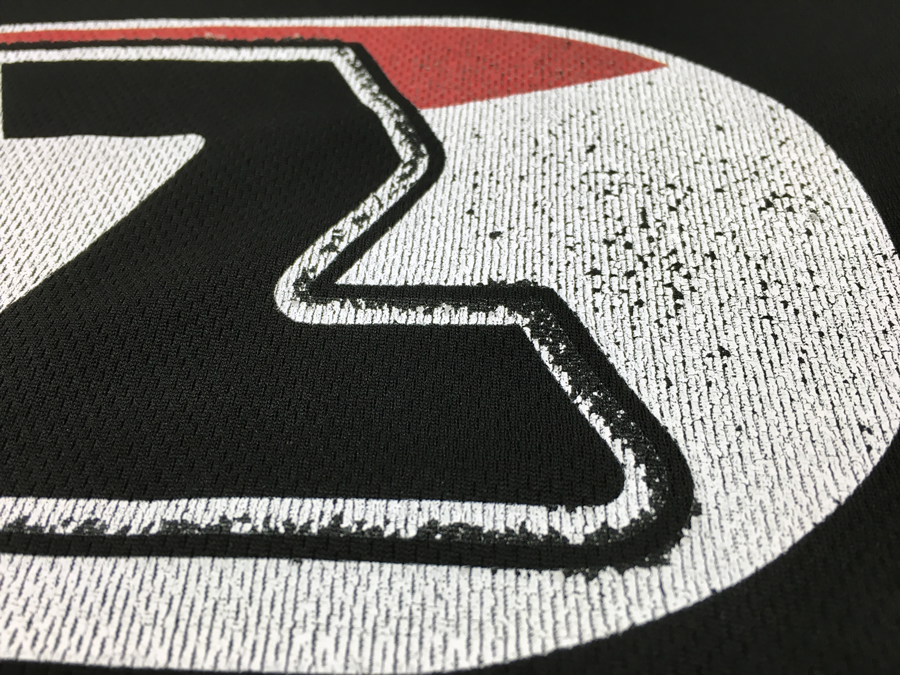

To help people understand some of the variables with different pretreatment and ink curing options, we wanted to do a side-by-side comparison to show what happens with the Image Armor E-SERIES™ DTG Inks and pretreatments. All the printing parameters and pretreatment application settings were the same for each print. The only difference was how […]

We wanted to thank everyone who stopped by our booth in Ft. Worth at the 2015 Imprinted Sportswear Show to talk to us about the Image Armor Inks and Pretreatments. A big thanks to George Git from Git Branded who talks about his experience with Image Armor in his printer.