The 2013 Philly NBM show proved to be an exciting time for Image Armor and those that have Ricoh based direct to garment printers.We wanted to thank Anajet for printing this fine sample for us at the show, which allowed Image Armor to do what it does best – protects […]

DTG

Forget Everything You Thought You Knew About Pretreatment Pretreatment in the past has been a huge deterrent for the newcomer to DTG white ink printing. You had to find “the sweet spot” or risk a failure of the print after the garment left your shop. This is not the way to run […]

Everyone at Image Armor would like to thank each and every person who helped make the launch of Image Armor Pretreatment Solutions a great success. We have been working feverishly to bring forth a new product to the DTG printing industry and with the help of everyone, the success has […]

As I write this, we have less than 24 hours before the official launch of Image Armor, which just happens to be Friday the 13th too. Everyone at Image Armor is excited about the launch and we are excited to hear from our users as they relate their experiences with […]

Thanks to some of our Image Armor Pretreatment beta testers it has been found that Image Armor Dark Shirt Formula works incredibly well with the new Epson SureColor F2000 direct to garment printer. As can be seen in the pictures above, without having been able to test various settings, a […]

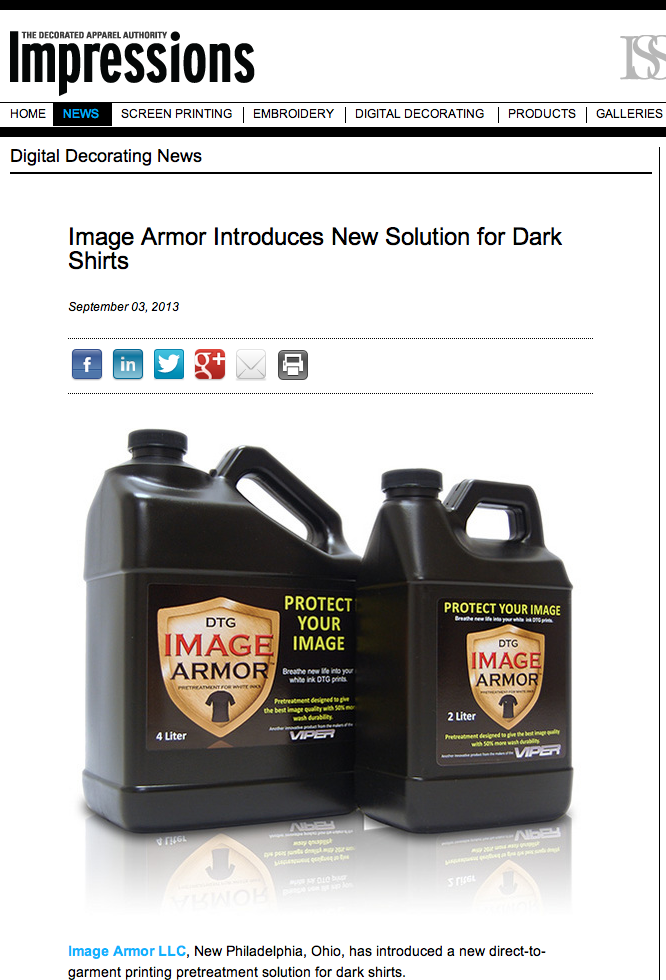

Image Armor has hit the pages of Impressions Magazine announcing the release of the new Image Armor Dark Shirt formula. Image Armor will be begin selling the new industry Dark Shirt formula through a select distribution channel starting on Friday the 13th, 2013. Image Armor will enhance print wash-ability by […]

Image Armor is getting excited about the launch of its new Dark pretreatment formula. This excitingly “scary” event is set to take place on 9-13-13….which is Friday the 13th! To celebrate this launch we will be offering an incredible special at introductory prices that will make it hauntingly attractive for […]

Image Armor is ramping up production to be able to meet demand when we release this exciting new pretreatment solution on 9-13-13. Some of the comments we’ve seen from our independent testing sites are… “This is like christmas coming early.” – spiderx1 on T-Shirt Forums “My confidence level in what […]