WHAT WE FOUND

During our routine printing and testing procedures we came across something that we though should be shared with our customers in regards to shirts, pretreatment and inks.

We were printing some white 100% polyester fabric shirts that were pretreated with 16g of the Image Armor LIGHT Shirt Formula. The interesting thing was that after we heat set the ink utilizing a cover sheet and light pressure at 356F for 35 seconds, we noticed around all of the printed ink a yellow type haze (See Figure 2).

This really confused us as we have never run into this before. At first we thought we had contaminated the pretreatment, the inks, or it was something completely different that we had done wrong. However, I used the same brand and style of shirt and printed it again. Coming off of the printer the image looked perfect – just as the first shirt did. But instead of heat setting “on contact” I decided to hover cure the ink on the heat press. The platen was lowered as far as possible and then let the shirt “bake”. The resulting image was what we see in the top of Figure 1. There was no “blowout” or yellowing around the printed design but I did notice that in comparison to other shirts that we’ve printed with the same exact design, the blacks were just not as “black” as they should be.

This got me wondering. There must be some type of reaction going on when the pressure and heat are applied to the garment to cure the ink. In comparison to older shirts from the same manufacturer the printed image was completely different in vibrancy and richness of colors. Again, the blacks were not as black as they should have been.

So, we took a different brand of shirt and printed the same exact image, with the same exact printer settings, and the same exact pretreatment amount, and ink cure time and pressure. What you see in the bottom of Figure 1 was a much bolder, darker black and no yellowing around the image. This got me wondering. Something was different and the only difference was the garment.

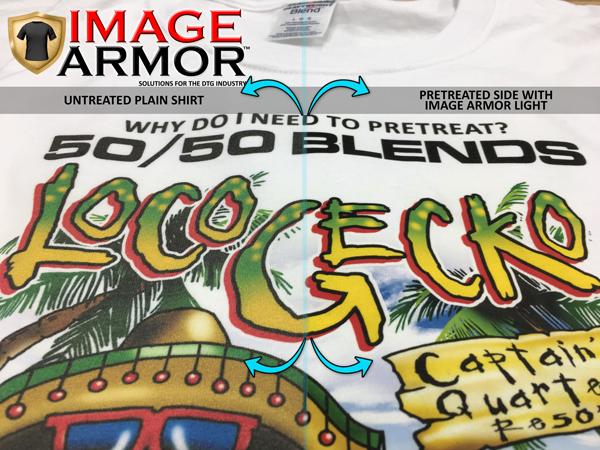

The interesting difference was the brand and style of the polyester fabrics. When we printed the same image on a 50/50 blended shirt the print result was the same as the bottom of Figure 1 – dark blacks and great colors with no yellow blowout.

This leads me to one conclusion. Some shirts may be post processed, or have some residual chemicals left in the shirt during washing/processing of the fabric that is reacting with the Image Armor LIGHT pretreatment and inks. But ONLY when applied under pressure of the heat press. This can be the only logical conclusion as on other brands of shirts, the design looked darker, more vivid and did not have the yellow halo. The 50/50 shirt we tested under the same conditions was perfect as was the 100% cotton shirt. There must be some type of coating as the black was not as dark or rich as it should have been which resulted in our yellowing haze.

CONCLUSION

Again, this threw me for a loop as it was the very first time I had ever come across this issue. We just wanted to bring this to everyone’s attention that if you run into something like this with the LIGHT Shirt formula on a cotton, blend, or 100% polyester shirt, this is the most likely explanation (unless the whole pretreated area yellows then it is either contaminated pretreatment OR residual chemicals, etc on the shirt). Image Armor can not control what process is done to the garments at the mill, but you can control what you use and what you find works best. This is why we always encourage users to test before running orders. You have to know what you’re dealing with before utilizing it in production.