Image Armor Has Done it Again

100% Polyester Printing with Regular Dupont Inks

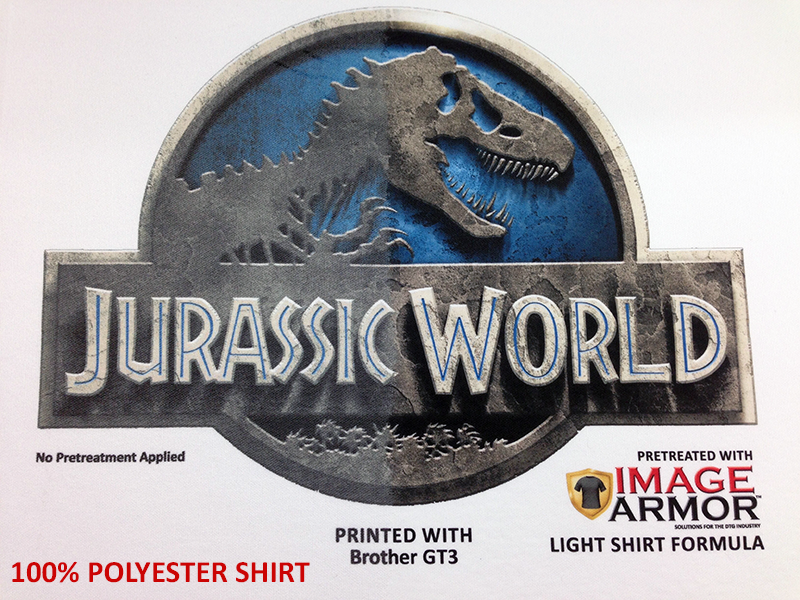

Doing the IMPOSSIBLE is what we’ve always strived to bring to our customers. Products that improve the DTG printing experience is what drives us to constantly improve the direct to garment printing process. Up until today, polyester printing with DTG has been limited to CMYK only on light or white colored polyester shirts.

However, in our constant pursuit of perfection, we’ve taken another step closer to the holy grail of DTG printing – white inks on black polyester fabrics. WE’RE NOT THERE YET, but the results of our process speaks volumes about the direction of the DTG market.

Utilizing our existing Image Armor LIGHT Shirt formula, we have been able to achieve commercially acceptable white ink prints on mid-colored polyester fabrics. The process is relatively straight forward, but we are expecting the RIP manufacturers to follow suit to give end users this ability from within the RIP itself to make it much easier to accomplish. Currently we have to do a little “workaround” to make the magic happen.

STEP 1: Pretreat the Shirt

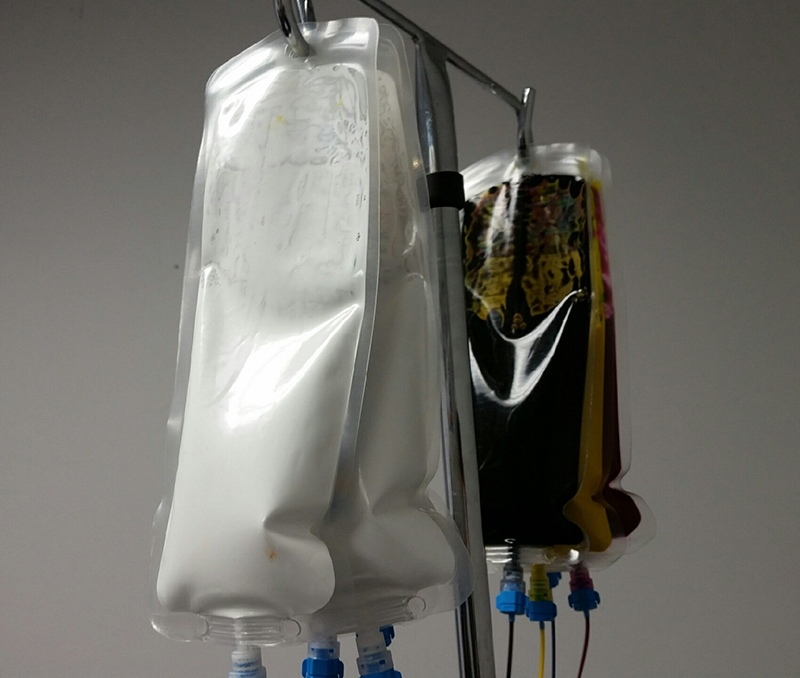

Pretreat the shirt using Image Armor LIGHT Shirt Formula. We utilized the Sport-Tek ST350 series 100% poly performance shirt (more on this in a minute) and applied 24 grams of pretreatment on the polyester shirt. The PT was then cured at 330F for two 20 second presses utilizing brown KRAFT type paper. I would not recommend using teflon as it will definitely shine up the shirt too much. The platen was raised to allow steam to escape and create a much more thorough and dry cure in between presses. We utilized a Stahl’s Hotronix Air Fusion heat press with 70 psi. A little experimentation might find that slightly more PT may help.

A NOTE ABOUT POLYESTER SHIRTS: We must note here at this point that some polyester shirts are better than others for printing. We did not some discoloration of the polyester fabric on the yellows and greys with the Sport-Tek ST350’s (it was not massive but some might find it unacceptable). However, we’ve seen some others that do not discolor. Sometimes this discoloration comes out in the wash, other times it does not. You’ll need to do some research on what polyester brand and shirts work best for your shop.

STEP 2: The UNDERBASE is Key

Printing the under base is key to getting these polyester shirts with white ink to print correctly. Normally some RIPs will print a solid under base of white under the entire design on a gold shirt like in our example above. However, for technical reasons you will get poor results if you do that with this process.

Printing the under base is key to getting these polyester shirts with white ink to print correctly. Normally some RIPs will print a solid under base of white under the entire design on a gold shirt like in our example above. However, for technical reasons you will get poor results if you do that with this process.

What you need to do is act as though you are printing the design (specifically the under base) on a black shirt. If your RIP allows you to utilize the black of the shirt color for the black in the printed design, then the RIP will not print any white ink where black is in the design (the shirt would be the black ink of the design). This process generally creates awesome fades on the DTG prints. This is also exactly what we want for our mid and light colored polyester shirts as far as the under base.

This may sound counter-intuitive, but black ink does not technically need an under base beneath it to look good on any shirt. You can see on our grey shirt to the right, what this white under base looks like when printed. Notice where black would be in the image there is NO white under base – this is extremely important. FAILURE TO ENSURE THE BLACK DOES NOT HAVE ANY WHITE UNDERBASE UNDER IT WILL RESULT IN A LESS THAN DESIRABLE FINAL PRINT ON POLYESTER FABRICS.

Note, your RIP must allow you to ONLY PRINT this under base. You DO NOT want to print the CMYK associated with this RIP’d design. Why? Again, we are not printing on a BLACK shirt. That’s why. So, you must be able to separately print the under base from the CMYK.

It might be noted at this time that the more white ink your printer can put down at this stage is crucial. Set it to a maximum amount of white ink. If you try to go back and print the under base again (as in a 2x under base) there will be massive bleeding of moisture around the edges of where the white ink and polyester meet. Try to bump up the white under base so it is dropping as much white ink as possible without over saturation to achieve a solid white layer of ink film.

STEP 3: Print the CMYK and HIGHLIGHT White

Now, we need to take the same exact image and print it in exactly the same place but with a CMYK + White Highlight option. In our RIP we utilized the CMYK + White highlight as though we were printing on a dark colored shirt (such as GOLD). This would normally print a solid white under base (which we do not use) and then the CMYK as normal with the highlight white.

What this achieves is allowing the BLACK ink to print directly onto the garment since there should be no white under base in those areas. And, we also get a highlight white to help augment the optical brightness of the white ink.

What this achieves is allowing the BLACK ink to print directly onto the garment since there should be no white under base in those areas. And, we also get a highlight white to help augment the optical brightness of the white ink.

Please note, you may need to reduce the white highlight percent lower to keep the CMYK (especially black ink) from mixing with the wet white highlight being printed. In our case, we utilized a 50% highlight and 100% white under base (higher values may work – some experimentation will be required). The CMYK was printed at a standard 65% setting. Your printer and ink set and polyester shirts might require some testing on settings, but it is worth it.

Once the shirt is printed, we have to heat set the ink.

STEP 4: Cure the Ink

Here is where it can get sticky. We strictly adhered to Duponts technical sheet of the cure time for their Artistri inks. 120 seconds in the heat press at 338F. I would not recommend higher temps due to the shirt dyes sublimating through the white ink. This seems to give an incredible great balance to wash ability and optical brightness, even on gold 100% polyester fabrics.

Our curing parameters we used a Hotronix Fusion heat press (non-pneumatic) at a pressure of 3-4 on the digital display. Do not use too much pressure and “kill” the inks by pushing them into the shirt.

NOW WHAT?

The shirt is printed, cured, and ready to roll. We’ve found excellent washability with the white ink and CMYK prints utilizing this technique without having to purchase any additional or different ink sets while at the same time utilizing our popular IMAGE ARMOR LIGHT Shirt Formula. This reduces the number of pretreatments needed to achieve great results with all of your current equipment.

Now, since you understand our process, a little experimentation on your end and happy customers will make the hard work on this end all pay off.

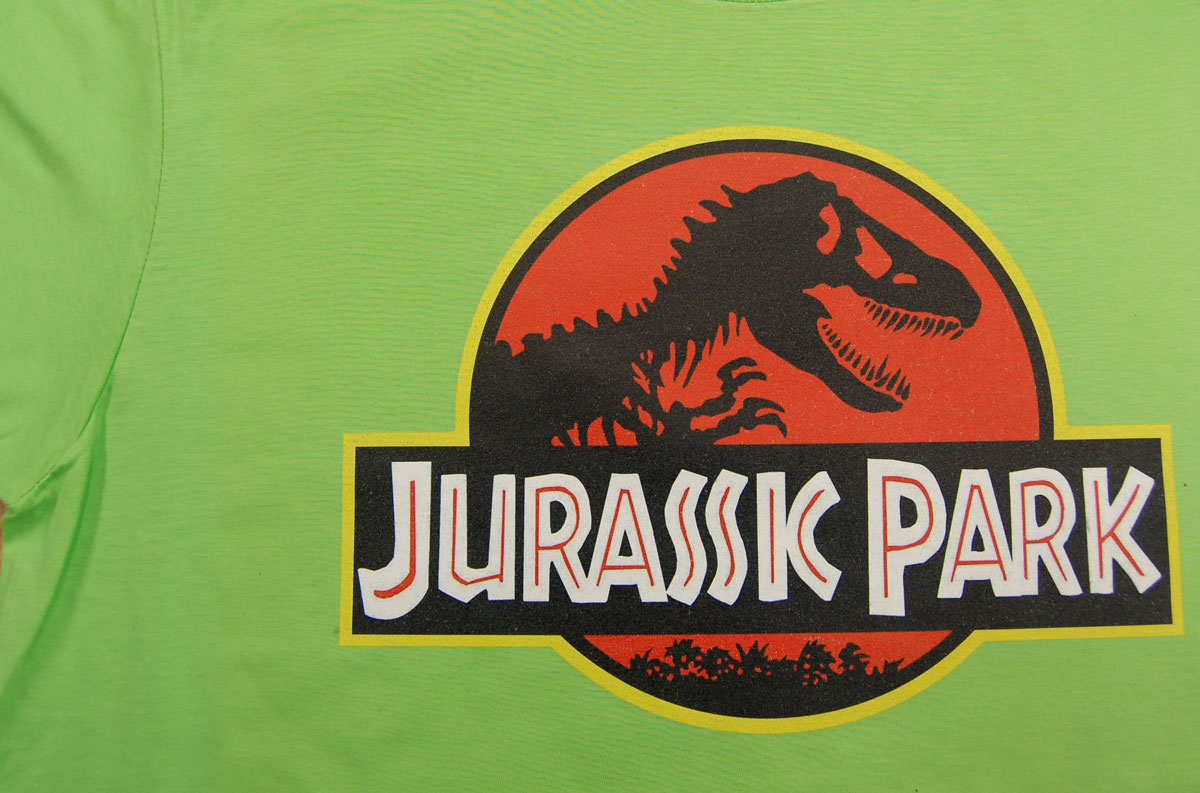

UPDATE: 5x WASH TESTING

Below is a picture of wash testing. The picture is a 5x wash in hot/cold and drying hot. Note the closeup inset of the picture. The ink is wrapped around the fibers of the polyester and interweaved – so it is not going anywhere. The drop in initial color vibrancy is maybe 5% like expected even on cotton but there is ABSOLUTELY NO HAND OR FEEL TO THE PRINT AT ALL AT THIS POINT.

UPDATE: 10x WASH TESTING

Below is a picture and closeup of the same shirt as above, washed and dried 10 times. There is still no noticeable difference between this and the 5x washing. The closeup reveals a better revelation of the white ink still wrapped around the individual fibers of the polyester shirt. The image is still extremely commercially acceptable after 10x washes.

[No pictures in galley]