We’ve been reviewing the process for people who are changing over to the Image Armor inks, or any other ink, from another brand of inks and have found several key factors that must be observed to ensure a more hassle free change over experience.

We’ve been reviewing the process for people who are changing over to the Image Armor inks, or any other ink, from another brand of inks and have found several key factors that must be observed to ensure a more hassle free change over experience.

Many DTG systems are not maintained properly, so we’ve released our technical bulletin below to make the change over easier. The point of this is to ensure that the entire ink delivery system is as clean as possible.

- It is required that all inks are changed over at the same time. The 35 second cure time is not compatible with the longer cure time of other ink sets.

- The DTG Printer must be flushed with an approved CLEANING solution. Before doing, please make sure:

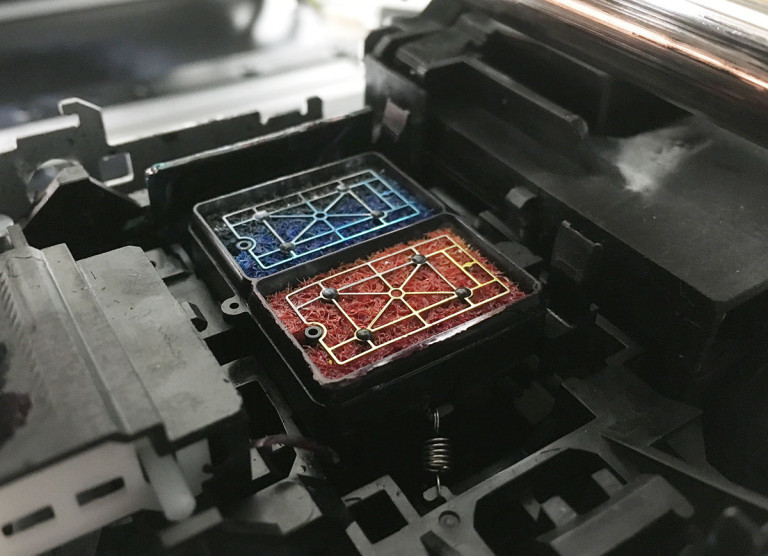

- Dampers should be replaced or re-conditioned AFTER flushing with the CLEANING Solution. Dampers are designed to collect “stuff” in the ink. The change over procedure may cause some of this “stuff” to move within the system which is undesirable. So, changing the DAMPERS after the flushing is optimal.

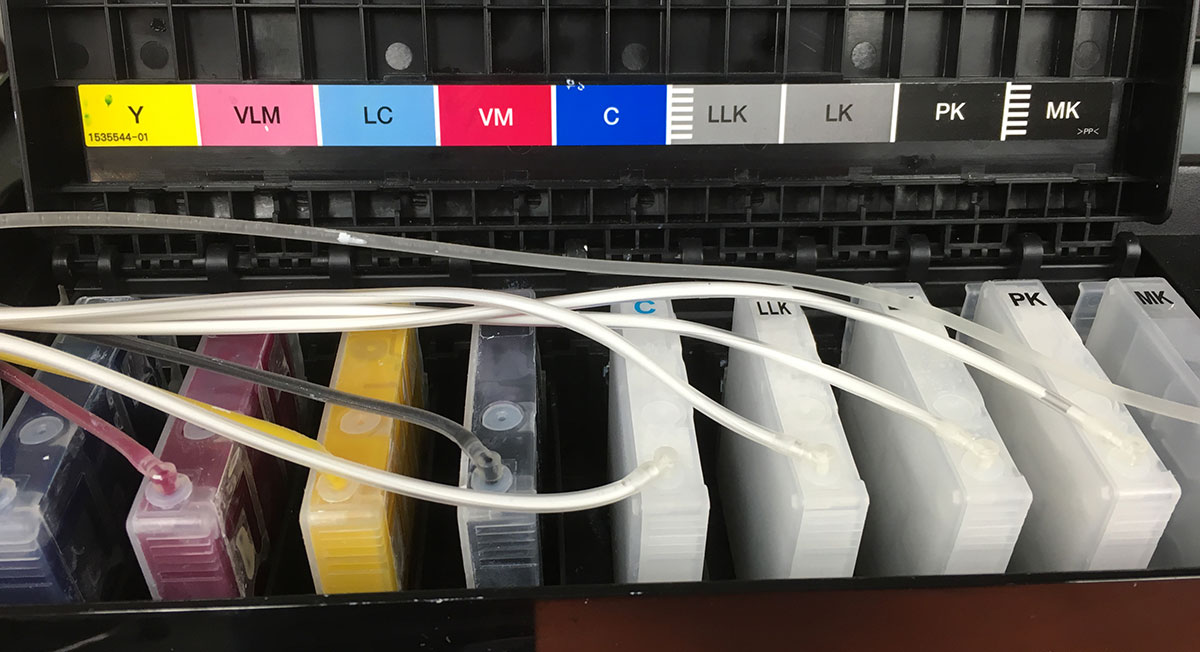

- If using CISS system, inspect, replace or recondition as necessary. A new CISS system removes any doubts.

- Do nozzle checks with CLEANING Solution to ensure all nozzles are firing. Some find clear acetate sheets or a light colored copier paper may help you see the nozzles easier.

- If everything is CLEANED properly, you can then introduce the new ink set.

Success of your change over is dependent upon your maintenance habits. In a “clean” or new system you should not have any issues with introducing the Image Armor Inks.

See below for general maintenance that should be followed to help reduce future issues, keeping you printing and making money.

We don’t want anyone to have a bad experience, and following these bullet points will make the changeover easier and more pleasant.

GENERAL MAINTENANCE TIPS

Maintenance is key and needs to be performed on a regular basis – especially on the white ink. Maintenance is key and needs to be performed on a regular basis – especially on the white ink.

|