DTG Tip – Blur the Lines Between Screen Printing and DTG

DTG Tip – Blur the Lines Between Screen Printing and DTG

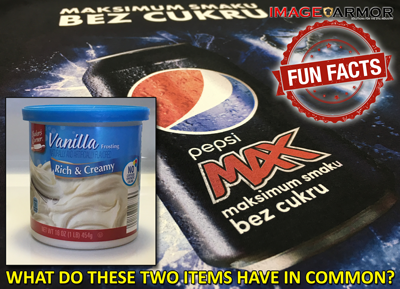

Due to the advances in pretreatment and ink technologies over the past year we have been able to blur the line between screen printing and DTG to the point where the untrained eye might not be able to tell the difference between the two processes.

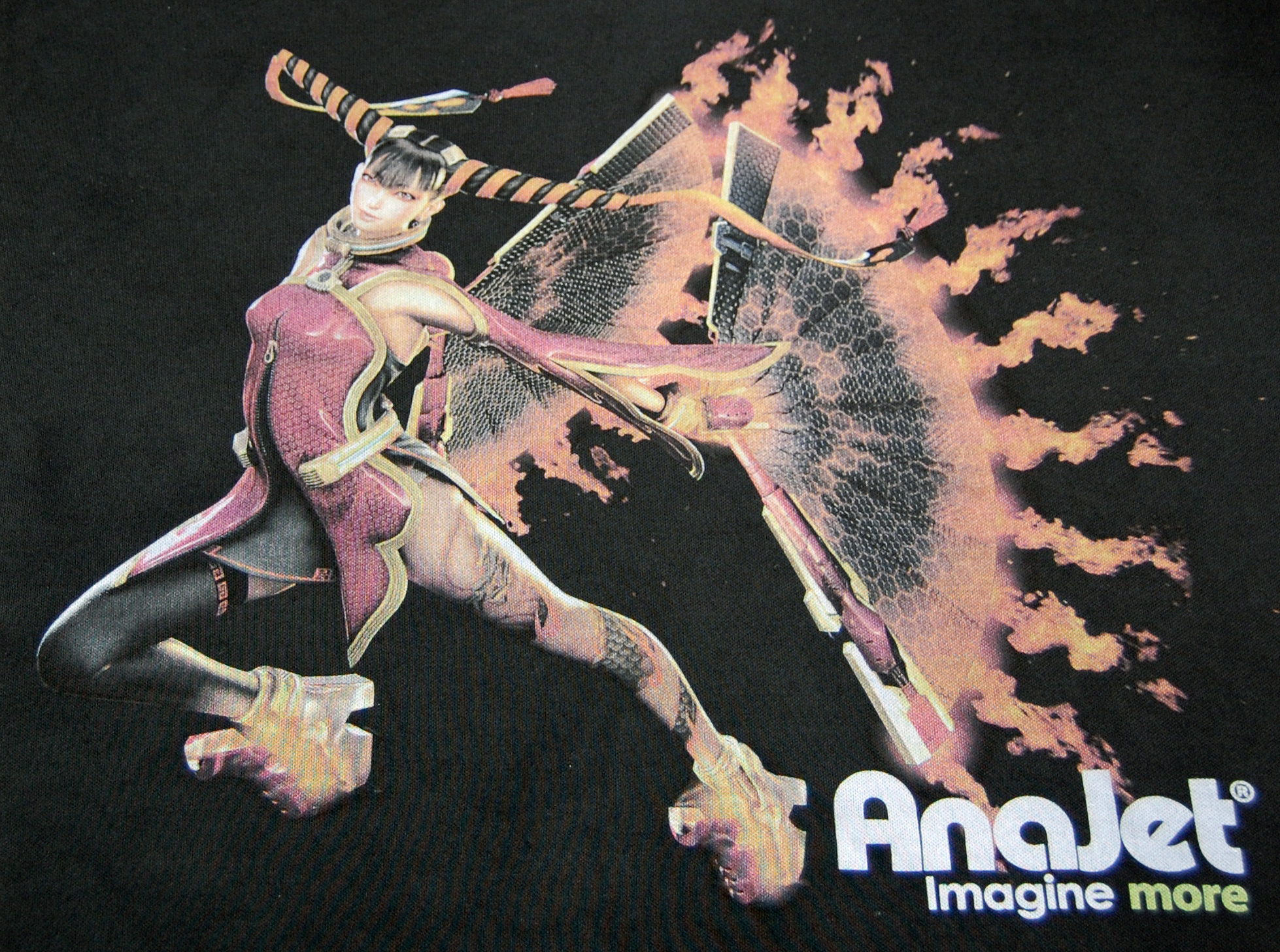

The key tip to achieve the “screen print” look would be to NOT use a heat press when curing the inks. The heat press will “flatten” or really smooth the printed ink surface. It is not that this looks “bad”, and some prefer it, but if you are trying to achieve the screen print look, try hovering just millimeters above the finished print with your heat press. You will definitely need to increase the exposure time to the heat to ensure that it is cured correctly (always test before doing this for end customers) or you might not get the ink cured and the customers returning shirts.

However, when done correctly, the ink surface will have a texture “feel” to the ink surface, simulating screen printing. In addition, utilizing the Image Armor new E-SERIES DTG inks increases the wash durability and wash fastness of the finished prints. Plus, you get incredible stretch characteristics that help keep the image looking better long term wash after wash.