The Holy Grail The Holy Grail

In the world of DTG white ink printing, 100% dark polyesters seem to be the Holy Grail. If only we could….In reality, polyester printing is a lot different than printing 100% cotton shirts. Most of the inks on the market today are designed to work with organic, 100% cotton garments. And they work really, really well. This is great if you are just printing 100% cotton. Our Image Armor Dark Shirt Formula (for 100% cotton shirts) has proven to raise the bar by improving wash ability by up to 50% or more while blowing the application window wide open.

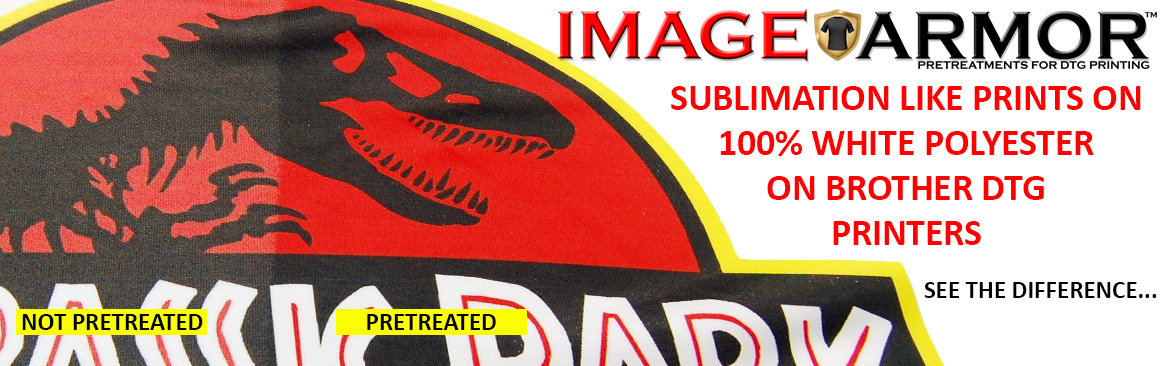

Previous pretreatments required you to apply just the right amount on the shirt to get acceptable wash results. Too much and the print looked great, but would wash off quickly once the customer took the garment home. Too little and the white ink was weak and didn’t wash well either. Image Armor has opened this application window gap by completely re-writing the formula for white ink DTG printing. This makes it much easier for newcomers to achieve success with their white ink printing attempts.However, polyester still remains “unattainable”. Even though Image Armor Dark Shirt Formula works well with white 100% polyesters (looks like sublimation and washes as such) and even fairs well on light colored polyester shirts. However, why is it we have issues with darker 100% polyester shirts?

The Reasons

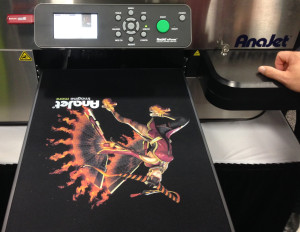

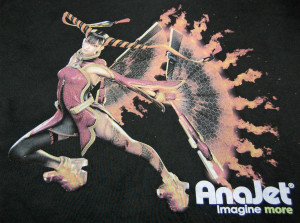

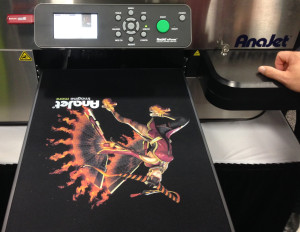

In our testing, we’ve seen incredible results from printing white ink on 100% black polyester shirts. As can be seen in the image to the left, this 100% black polyester shirt looked great on the shirt prior to heat setting. However, after curing the ink the image appeared to fade. In the past, we would have blamed dye migration which is still very much an issue on red or red family dye colored shirts. However, I don’t believe that we can leave all the blame at the feet of dye migration.

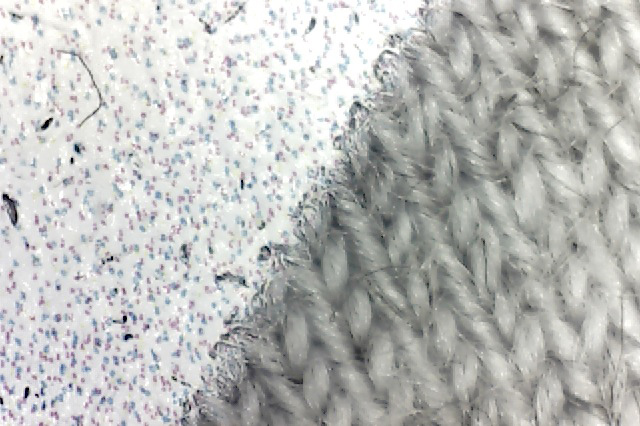

Traditionally, white ink would bridge the gap on the shirt and the pretreatment would allow the ink film to stay on top of the shirt as seen in the image below.

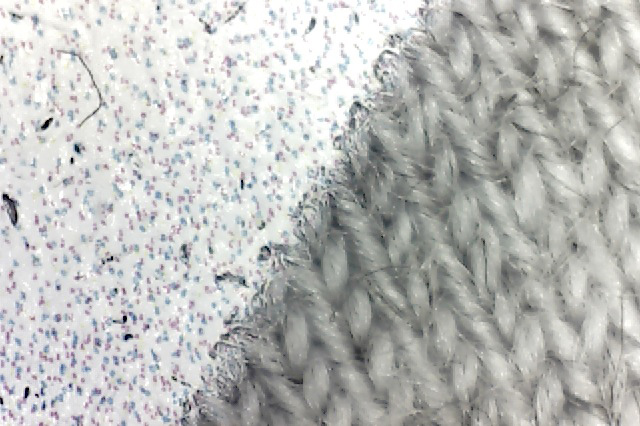

Here you can easily see where the white ink ends and is sitting on the top of the grey shirt. Also note how tight the weave is for this 100% cotton shirt. This is why you get better prints off of good, high quality ring-spun shirts with a really tight weave and thin thread size. You are basically creating a smooth, flat – think of it as photo glossy paper – surface for the white ink to print on and to which to adhere. The resulting prints are obviously of very high, smooth quality. Here you can easily see where the white ink ends and is sitting on the top of the grey shirt. Also note how tight the weave is for this 100% cotton shirt. This is why you get better prints off of good, high quality ring-spun shirts with a really tight weave and thin thread size. You are basically creating a smooth, flat – think of it as photo glossy paper – surface for the white ink to print on and to which to adhere. The resulting prints are obviously of very high, smooth quality.

Now, let us take a look at a closeup via USB microscope at the polyester shirt. The left image is the original 100% polyester shirt, washed 10 times. You will notice the image does look faded – the white and colors are “muted”. However, take a look at the image to the right. This is a close up of the white print on the 100% black polyester fabric. The “fade”, or color loss, is due to halftoning. This would be similar to what is experienced when you take a 100% white ink film and halftone it 50% – resulting in a “grey” looking print vs a solid bright white (it is after all 50% of the optical brightness). The weave of the fabric is much looser allowing less fabric for the white to totally adhere to creating the illusion of a faded white.

However, the close up reveals much more. The ink is still extremely white and adhering extremely well to the fibers BUT the air gaps in the weave of the fabric (which allows for breathability and is why people like the polyester performance fabrics) leave nothing to which our white DTG inks can “stick”.

As can be seen in the image to the right, above, the ink is adhering quite well. However, the open weave of the fabric and due to the nature of polyester, we have a lot of “open” space which allows the black polyester to show through the white printed area effectively fading the actual image vibrancy.

This is part of the reason why we are still having difficulties printing white ink on dark polyester fabrics.

What Does this Mean for DTG Printing in the Future?

What this means is that we still have a ways to go with white ink printing on dark polyester fabrics. However, our goal at Image Armor is to bring you the best possible products. We have already taken 100% polyester printing further than any other company to date. And we have the drive and ideas that we believe will help bring this area of printing to reality.

|

Here you can easily see where the white ink ends and is sitting on the top of the grey shirt. Also note how tight the weave is for this 100% cotton shirt. This is why you get better prints off of good, high quality ring-spun shirts with a really tight weave and thin thread size. You are basically creating a smooth, flat – think of it as photo glossy paper – surface for the white ink to print on and to which to adhere. The resulting prints are obviously of very high, smooth quality.

Here you can easily see where the white ink ends and is sitting on the top of the grey shirt. Also note how tight the weave is for this 100% cotton shirt. This is why you get better prints off of good, high quality ring-spun shirts with a really tight weave and thin thread size. You are basically creating a smooth, flat – think of it as photo glossy paper – surface for the white ink to print on and to which to adhere. The resulting prints are obviously of very high, smooth quality.