New Philadelphia, Ohio March 8th, 2019 – Image Armor is thrilled to announce that our IA Light and Ultra pretreatment formulas for the Direct to Garment Industry are OEKO-TEX®, Eco-Passport Certified as of February 2019. ECO PASSPORT by OEKO-TEX® is an independent testing and certification system for chemicals, colorants and auxiliaries used […]

Light Shirt Formula

Image Armor Inks Take Over Russia Image Armor is proud to announce that GarmentInks.ru located in Moscow, Russia is now carrying the entire line of Image Armor pretreatments as well as the E-Series inks for Epson repurposed printers. Now DTG printers located throughout Russia can utilize Garmentinks.ru to purchase the […]

COME TO LONG BEACH JULY 20th-22nd TO SEE WHY YOU SHOULD PRETREAT EVERY WHITE T-SHIRT Image Armor is excited to be exhibiting at the Long Beach ISS July 20th – 22nd at the Long Beach Convention Center. Stop by in booth #1010 to talk about DTG and see why you […]

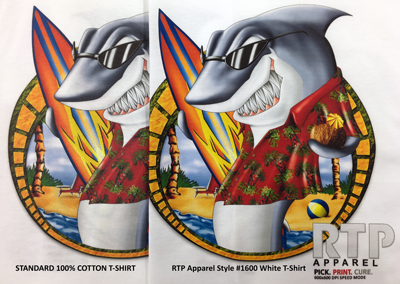

We wanted to show you EXACTLY why you want to use the RTP Apparel garments that utilize our Image Armor pretreatment technology. This is especially true for a white T-Shirt. We’ve heard from many DTG’ers the question – “Why pay more, or a premium, for a white T-Shirt when you can purchase […]

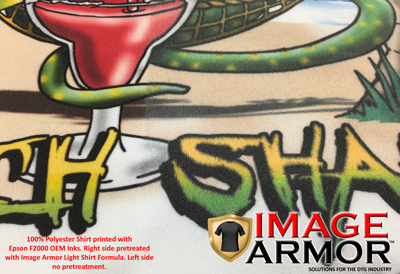

UPDATE: We have been continuing the wash testing of the Epson F2000 OEM inks printed on a 100% polyester white shirt. The left side of the shirt had been pretreated with Image Armor LIGHT Shirt Formula. The shirt was then printed with original Epson OEM inks. As you can see in the image to […]

Printing 100% Polyester Shirts with the Epson F2000 DTG Printer Printing on 100% polyester fabrics has always been problematic. The colors are not vibrant, the image clarity is fuzzy due to bleeding, and the wash durability is not the best. There have not been many options for the Epson F2000 DTG […]

Rich Gamba from Shelter Cove Embroidery talks about his experience with using his Brother GT-381 DTG printer and Image Armor LIGHT Shirt Formula to improve the garments he prints for his customers.

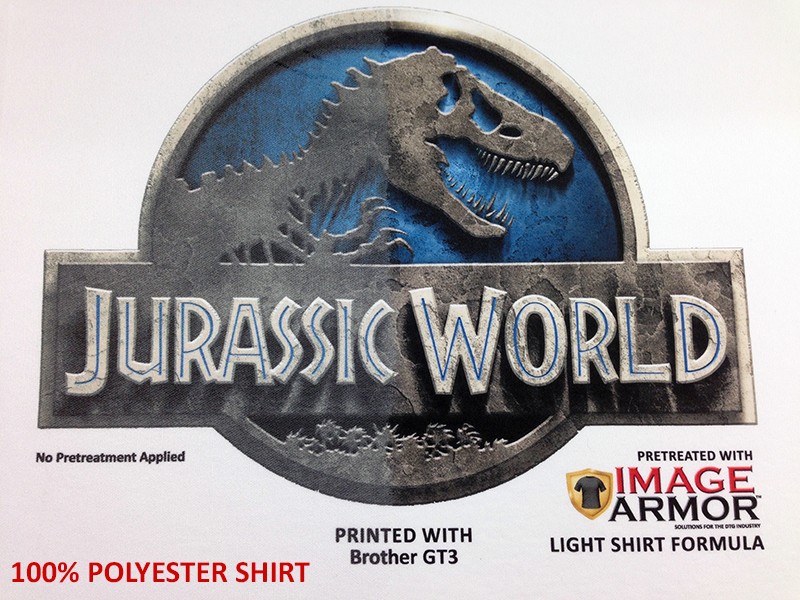

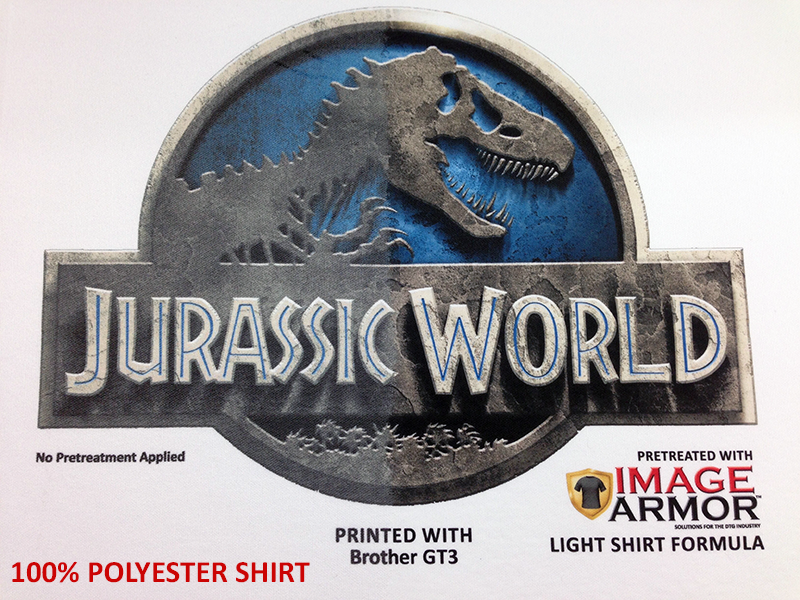

100% Polyester & Pretreating REALLY Does Make A Difference Maker sure to stop by our booth at the Long Beach Printwear Show July 23-25th, 2015. Image Armor will be in Booth #932 on the end aisle and you can check out this incredible print in person. We printed this on a […]

100% POLYESTER PRINTING WITH IMAGE ARMOR Maker sure to stop by our booth at the Long Beach Printwear Show July 23-25th. Image Armor will be in Booth #932 on the end aisle and you can check out this incredible print in person. We printed this on a 100% white polyester […]

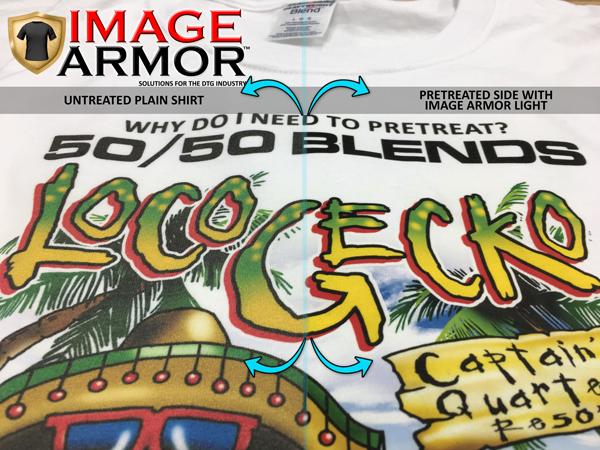

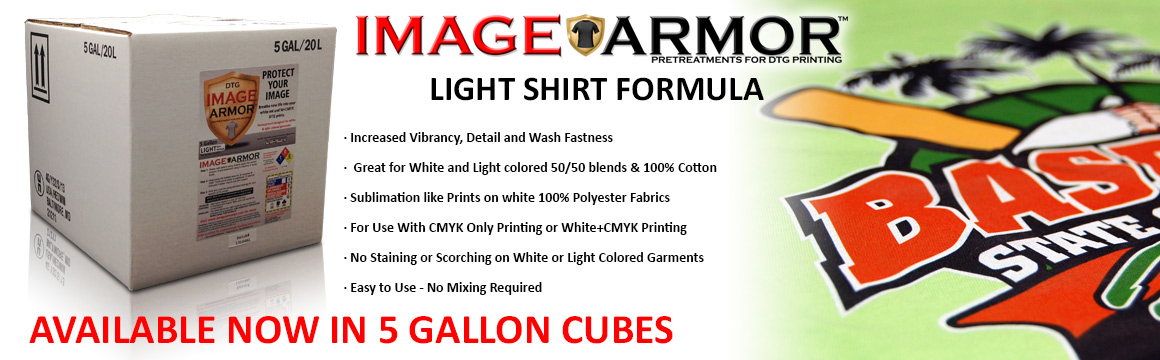

Image Armor LIGHT Shirt Formula is available now in 5 gallon CUBE containers. This new LIGHT Shirt Formula increases vibrancy and detail while improving wash fastness for CMYK and White+CMYK prints. It is great for achieving sublimation like prints on white 100% polyester shirts while increasing printing options on 50/50 […]