NEW SPREADSHEET SHOWS YOU HOW MUCH EXTRA YOU CAN PUT INTO YOUR POCKET JUST BY USING IMAGE ARMOR INKS We thought this would be a great little spreadsheet to help everyone understand how much more money that they can put into their pocket over the course of a year simply by switching […]

DTG

The American Revolution began in 1765 as the result of the King of England imposing taxes upon them without any representation. Through a very tumultuous time from 1765-1783, the American people fought for their freedom to be the Captains of their own destiny. They shook off the chains that held them down […]

For any users who use are looking to switch to the Image Armor E-SERIES DTG inks and are utilizing a WIMs (White Ink Management) system to recirculate their white inks, or a printer that utilizes a standard filter like the one seen to the left (usually they are inline somewhere […]

I have recently been told by several people that Simple Green cleaner is being recommended by printer manufacturers to flush their DTG printer. While Simple Green is a great general cleaner for a variety of surfaces you definitely DO NOT want to use this in your DTG printer. One person […]

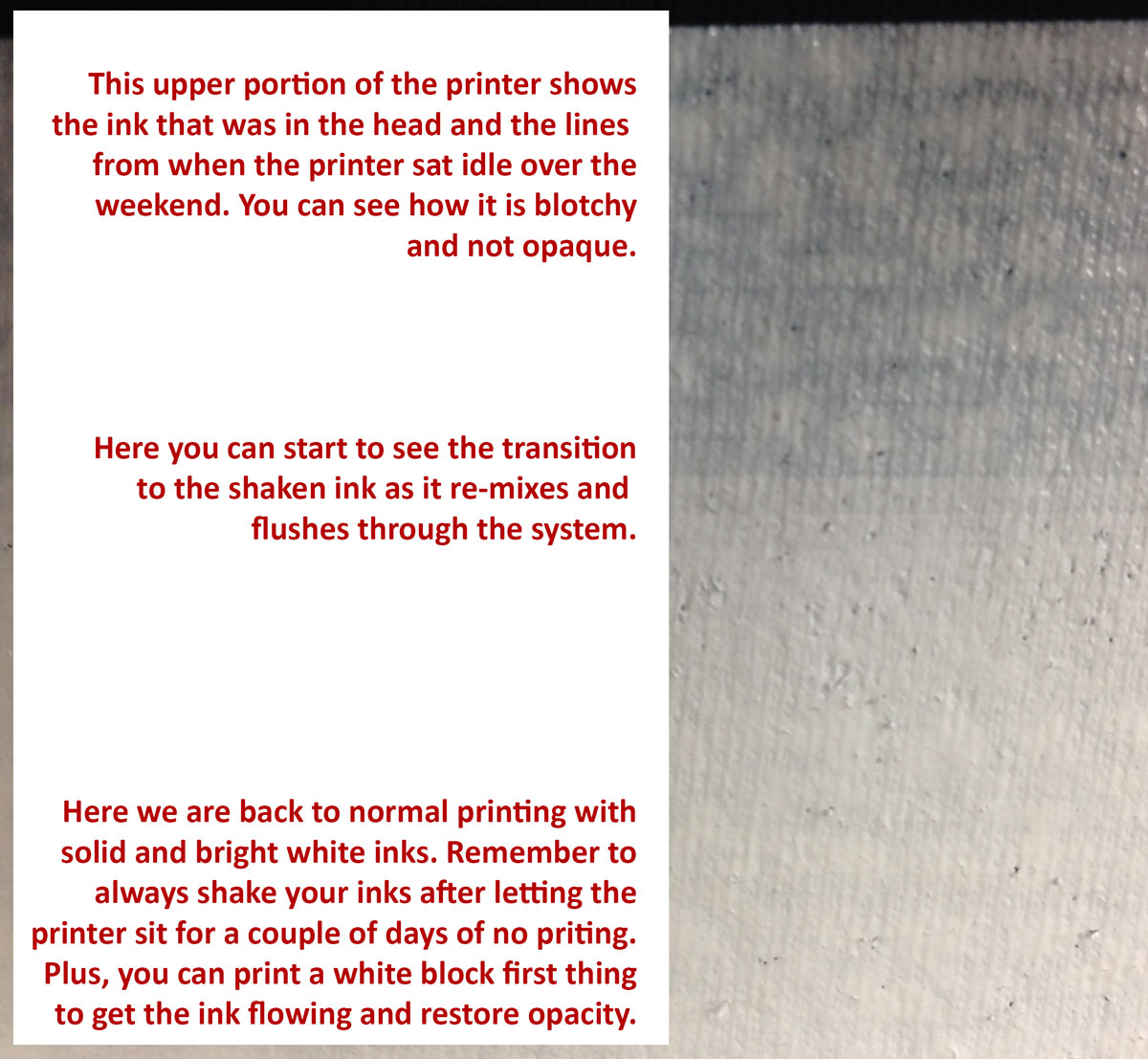

I thought this would be prudent to post for people to understand the physics of the inks, especially after a long weekend or several days of no white ink printing. The photo to the left shows what I saw this morning after 2 1/2 days of no printing. I shook the ink […]

J&B Sewing of Newport are now carrying the new Image Armor E-SERIES DTG inks for Epson re-purposed printers in the United Kingdom. The new E-SERIES inks are designed with incredible wash fastness and ease of use within the multitude of printers available on the market. Business owners will come to […]

Updated 3:10 p, 9/3/15 2:08p 9/8/15 Image Armor, LLC is proud to announce that in an industry first for Epson re-purposed printers we have achieved white ink printing with superior wash fastness on black 100% polyester fabrics. Previously there were serious dye migration and wash issues associated with trying to print white […]

Image Armor, LLC is proud to announce that Spectra DTG which produces the cost effective Spectra 3000 Direct to Garment printer is now exclusively shipping all new printers with the Image Armor E-SERIES™ DTG Inks. The new E-SERIES™ inks designed with a 35 second white ink cure time and improved […]

When you are changing from one ink set to another you want this process to go as smoothly as possible. You don’t need any issues or complications but often in the race to save a few dollars you might end up costing yourself hundreds of dollars in repairs. The process of cleaning […]

Image Armor Has Done it Again 100% Polyester Printing with Regular Dupont Inks Doing the IMPOSSIBLE is what we’ve always strived to bring to our customers. Products that improve the DTG printing experience is what drives us to constantly improve the direct to garment printing process. Up until today, polyester […]