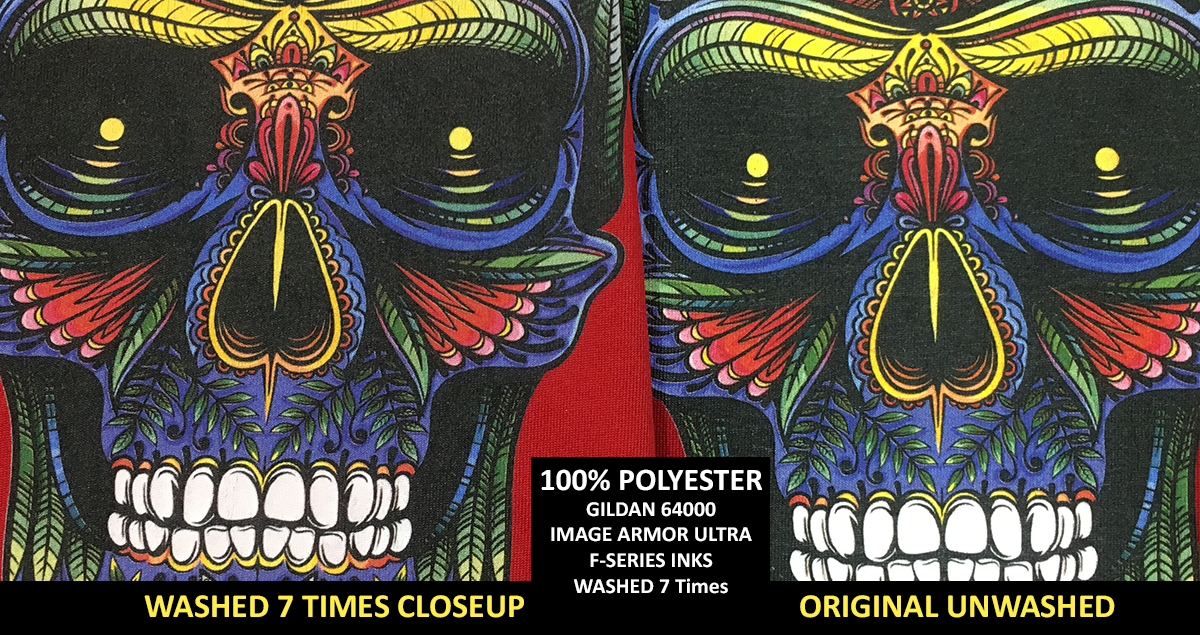

PRINTING 100% POLYESTER WITH THE EPSON F2100 We just got our new Epson F2100 DTG printer in for testing and wanted to show you what you can do with the Image Armor DTG pretreatment products. We are excited to report our first tests and we started with 100% Black polyester […]

direct to garment

Direct To Garment printing should be easy, right? Just load the graphic, the shirt, and press the PRINT button. But anyone who has ever done DTG printing knows that there is a LOT more to it than just that. Even though there are a lot of moving parameters in DTG […]

[siteorigin_widget class=”WP_Widget_Media_Image”][/siteorigin_widget] Streamlined Pretreatment Production via RFID Now Available In an effort to continually improve the Direct To Garment process i-Group Technologies has always tried to make pretreating easier. The Viper MAXX pretreatment machine is now also RFID capable with the addition of a simple and inexpensive RFID reader that […]

TRY BEFORE YOU BUY OFFER! GET FREE SAMPLES OF IMAGE ARMOR LIGHT AND ULTRA SHIRT FORMULAS Image Armor is so confident that our DTG Pretreatment Solutions can make a difference in your shop that we are willing to send to you a free sample quart of the LIGHT Shirt and […]

TRY BEFORE YOU BUY OFFER! GET FREE SAMPLES OF IMAGE ARMOR LIGHT AND ULTRA SHIRT FORMULAS Image Armor is so confident that our DTG Pretreatment Solutions can make a difference in your shop that we are willing to send to you a free sample quart of the LIGHT Shirt and […]

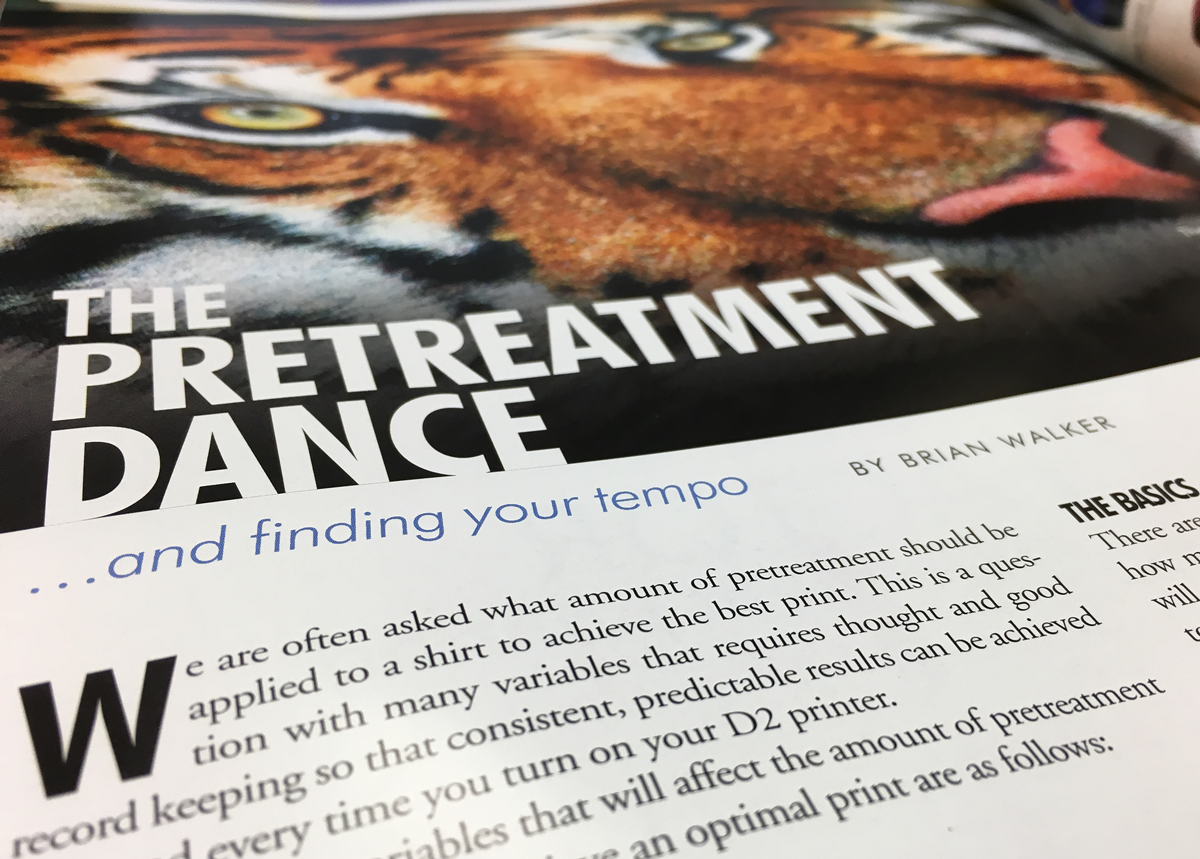

The Pretreatment Dance – What is the Right Amount of DTG Pretreatment? A very often asked question in Direct To Garment printing is “How much pretreatment do I need to apply to the shirt?”. For the new DTG printer (and those who’ve printed for a while) this is a very […]

Image Armor Gives RTP Apparel a Longer Shelf Life – 3+ Years Image Armor is proud to announce that our partnership with RTP Apparel, the world’s first mass produced DTG Ready To Print apparel, has provided these garments with a longevity that no one else can match to date. We […]

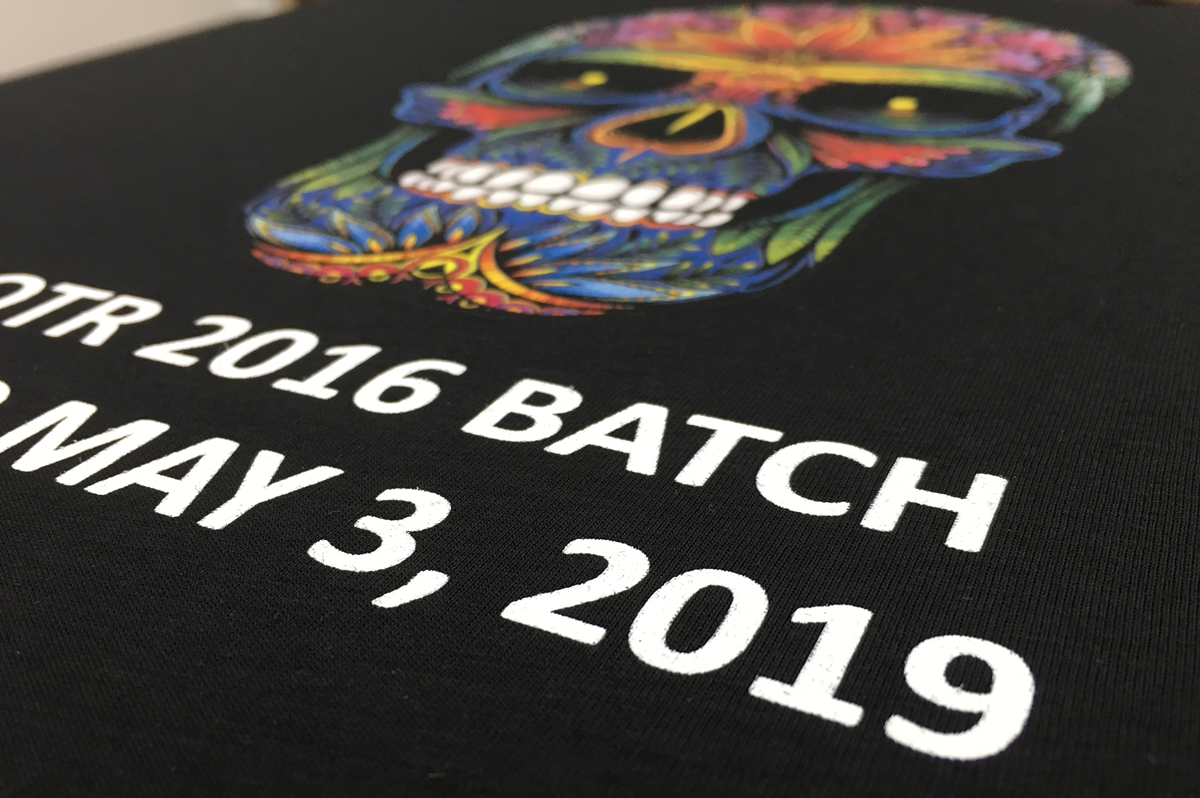

100% Red Polyester Printing with Image Armor ULTRA PRINTING 100% POLYESTER WITH IMAGE ARMOR ULTRA We’ve been hearing a lot lately about this pretreatment, this ink, etc. that will allow us to print on polyester fabrics. For the last 4 years Image Armor pretreatments have allowed this to be accomplished. […]

Image Armor is proud to announce that we have additional distribution in Italy for the Image Armor product line. DoctorPlotter.com now carries the full line of Image Armor pretreatment solutions and inks. Located in Giaveno Italy, DoctorPlotter.com carries a wide array of direct to garment supplies. Our new distributor carries […]

Image Armor is proud to announce in our effort to be as environmentally conscious as possible that all of our pretreatments have recently passed a battery of tests and have been found to be compliant with the following: CPSIA Compliant – Consumer Product Safety Improvement Act California Prop65 Complinat 100% […]