It’s fun for us to do the trade shows circuit with the Image Armor products. We often get DTG printers who stop by our booth and have never tried any of the Image Armor pretreatments. When they see what our pretreatments are capable of letting them achieve, they start to get excited. […]

CMYK

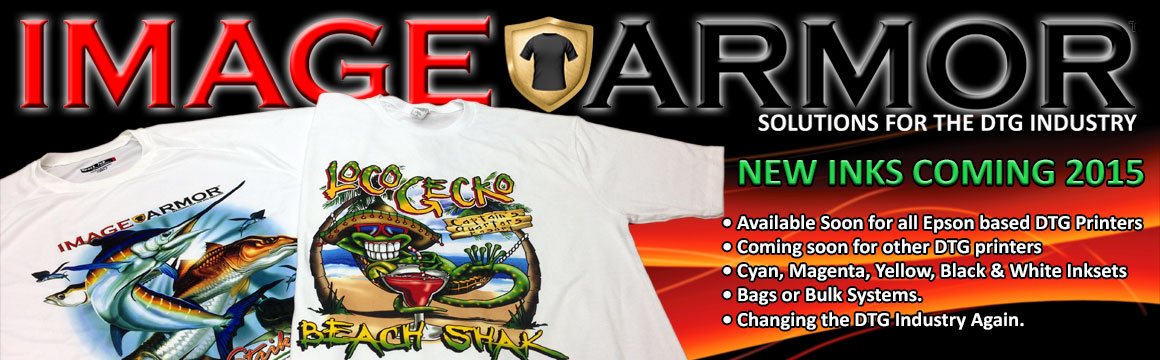

Image Armor, LLC is excited to announce that we will be releasing a new line of DTG inks for the direct to garment printing industry in 2015. What we did for the industry with our line of pretreatments we plan on doing again with our new CMYK and white ink […]

Everyone at Image Armor would like to thank you for a great 2014 and wish you a very Merry Christmas. And we hope that 2015 is very profitable for you, your family, and your company. Here at Image Armor, we hope to be able to help you be more profitable […]

Image Armor Has Done it Again 100% Polyester Printing with Regular Dupont Inks Doing the IMPOSSIBLE is what we’ve always strived to bring to our customers. Products that improve the DTG printing experience is what drives us to constantly improve the direct to garment printing process. Up until today, polyester […]

Image Armor LIGHT Shirt Formula is available now in 5 gallon CUBE containers. This new LIGHT Shirt Formula increases vibrancy and detail while improving wash fastness for CMYK and White+CMYK prints. It is great for achieving sublimation like prints on white 100% polyester shirts while increasing printing options on 50/50 […]

Image Armor is proud to announce the release of the new Image Armor LIGHT Shirt Formula for White and Light Colored garments. The new LIGHT Shirt Formula expands your printing capabilities beyond anything you thought possible with increased vibrancy and wash fastness like you’ve never seen before in DTG printing. […]

GET FINISHED PRINTS THAT LOOK LIKE HIGH END SCREEN PRINTS WITH A DTG PRINT Traditionally the standard 50/50 shirts has not been a great product to print with the DTG process. Untreated shirts would have very weak, fuzzy, and non-bright images. The pretreatments that were available on the market were […]

Image Armor thought that many new users might be able to learn what happens when ink is printed over an area of a garment with no pretreatment. When pretreatment is not applied or not applied correctly to a shirt the results usually render the shirt unsellable. In the photo above […]

15X WASH/DRY CYCLES – 100% COTTON FABRIC TEST PRINT Here’s the 15X washing and drying of our soon to be released Light Shirt Formula. This formula is designed to be applied to white and light colored shirts that are 100% cotton, 50/50 blends and 100% polyester garments.The photo to the […]

100% POLYESTER FABRIC TEST PRINT 10X RESULTS Here’s the 10X washing and drying of our soon to be released Light Shirt Formula. This formula is designed to be applied to white and light colored shirts that are 100% cotton, 50/50 blends and 100% polyester garments.The photo to the left is […]