You may also like

Everyone has been asking about Image Armor and we wanted to start bringing you some informative articles on using Image Armor.The current […]

Image Armor Has Done it Again 100% Polyester Printing with Regular Dupont Inks Doing the IMPOSSIBLE is what we’ve always strived to […]

SHAKE IT UP BABY The Beatles said it best in their song “Twist and Shout” that you should “Shake It Up Baby”. […]

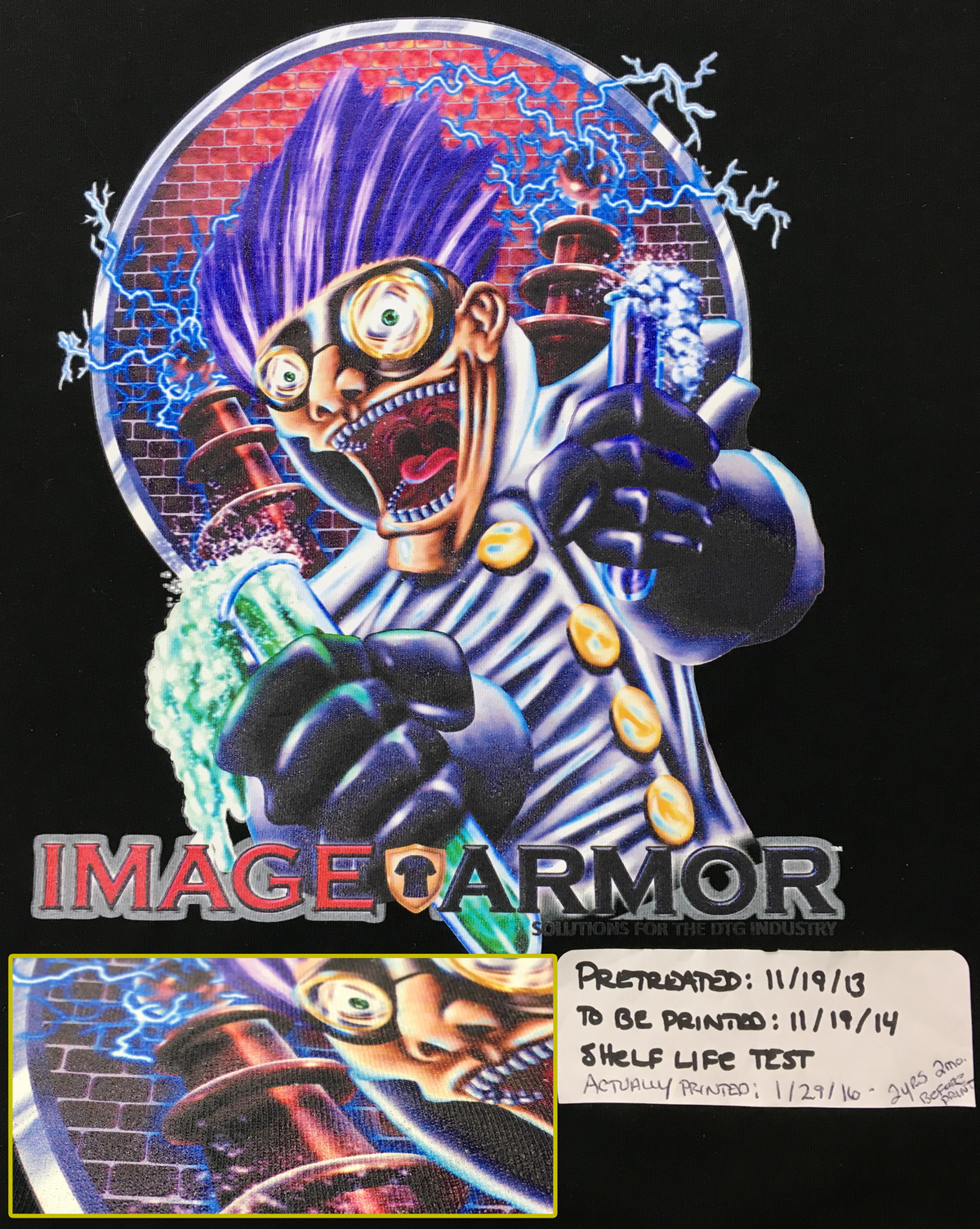

NOTE: This is a re-post of an article we posted in January of 2016. We get a lot of inquires about this, […]