100% POLYESTER FABRIC TEST PRINT 10X RESULTS Here’s the 10X washing and drying of our soon to be released Light Shirt Formula. This formula is designed to be applied to white and light colored shirts that are 100% cotton, 50/50 blends and 100% polyester garments.The photo to the left is […]

Education

100% POLYESTER FABRIC TEST PRINT 5X RESULTS We wanted to update you to show you the results of our testing with a soon to be released Light Shirt Formula. This formula is designed to be applied to white and light colored shirts that are 100% cotton, 50/50 blends and 100% […]

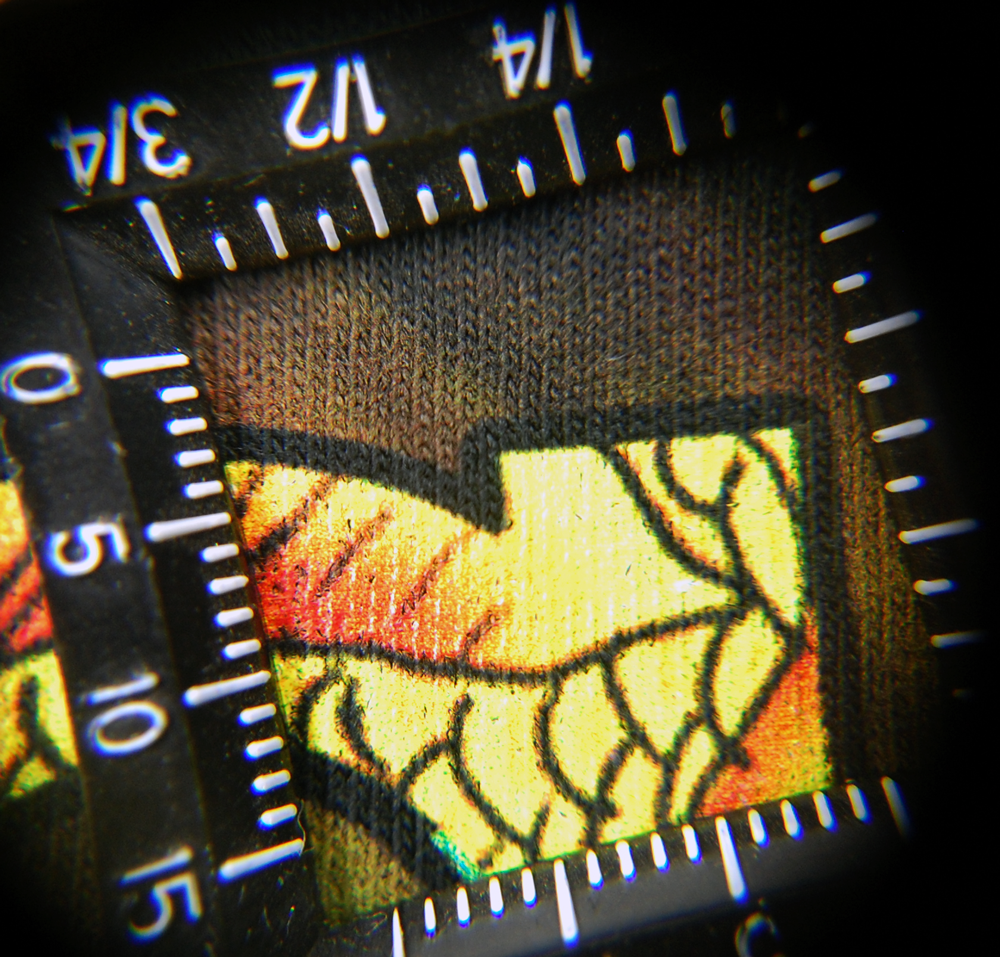

What is Going On? There are many factors when pretreating you should pay attention to to ensure you get the best, possible printing surface for your white ink.In this image you can see the pretreatment has crystallized. Normally, this will not happen however there are circumstances where it will crystallize […]

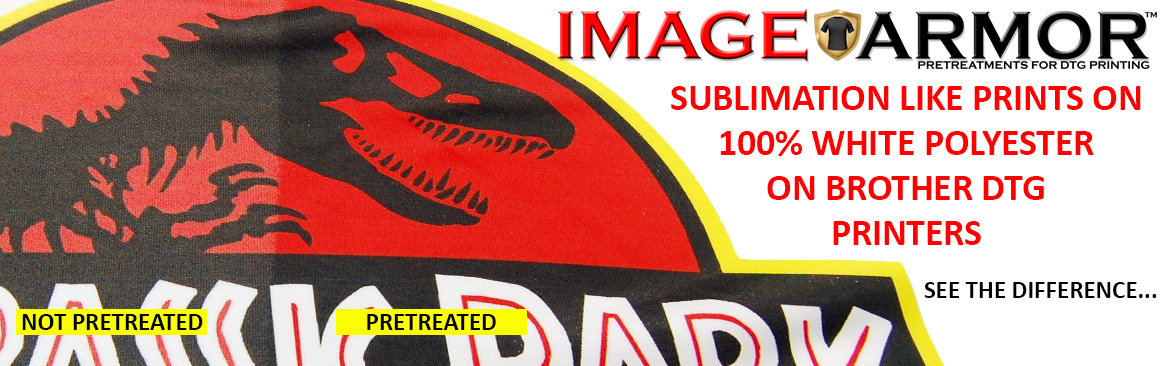

100% White Polyester Printing on Brother DTG If you want to get sublimation like prints from your Brother direct to garment printer, it is now possible with Image Armor.We used a Sport-Tek 100% polyester shirt and pretreated with Image Armor (18 grams in this example) and the results were absolutely […]

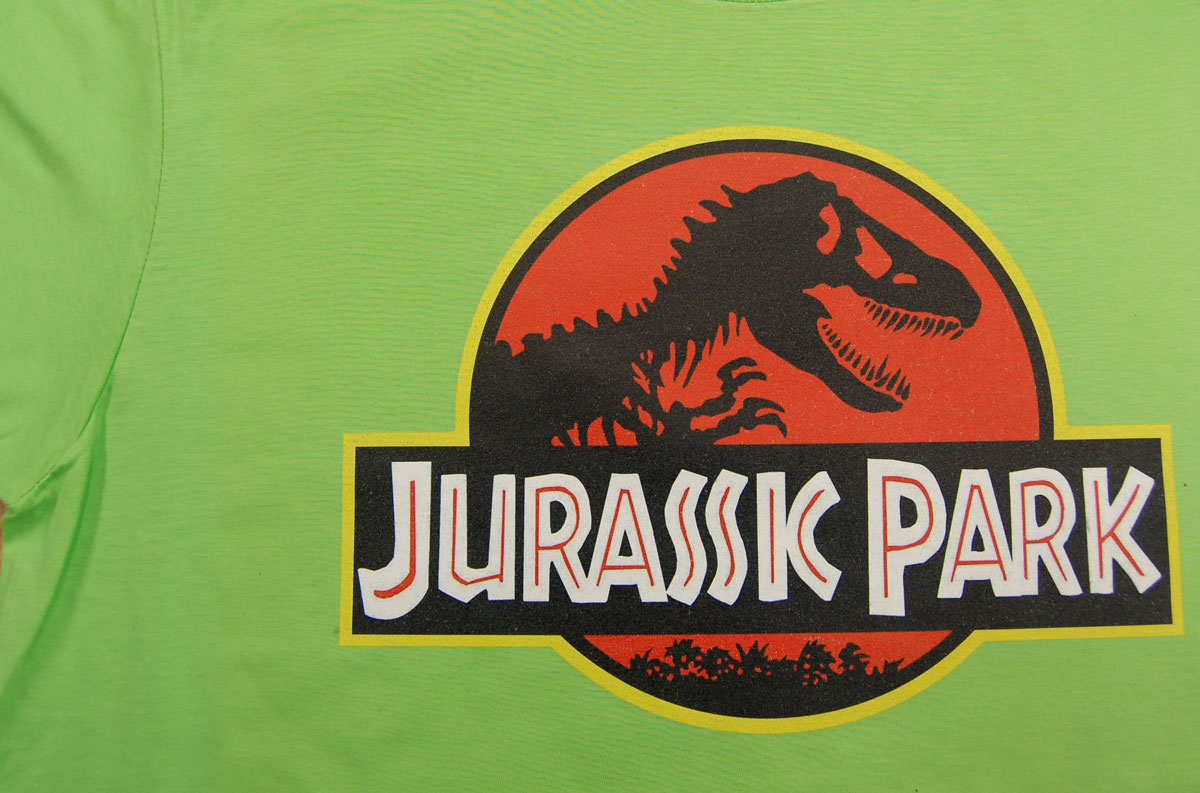

What We Printed In our continuing efforts to educate our customers, we wanted to show a Hanes Nano T in Lime Green printed with Image Armor Dark Shirt Formula.The shirt was pretreated with 18 grams of Image Armor Dark Shirt Formula, and heat set 2x presses for 20 seconds at […]

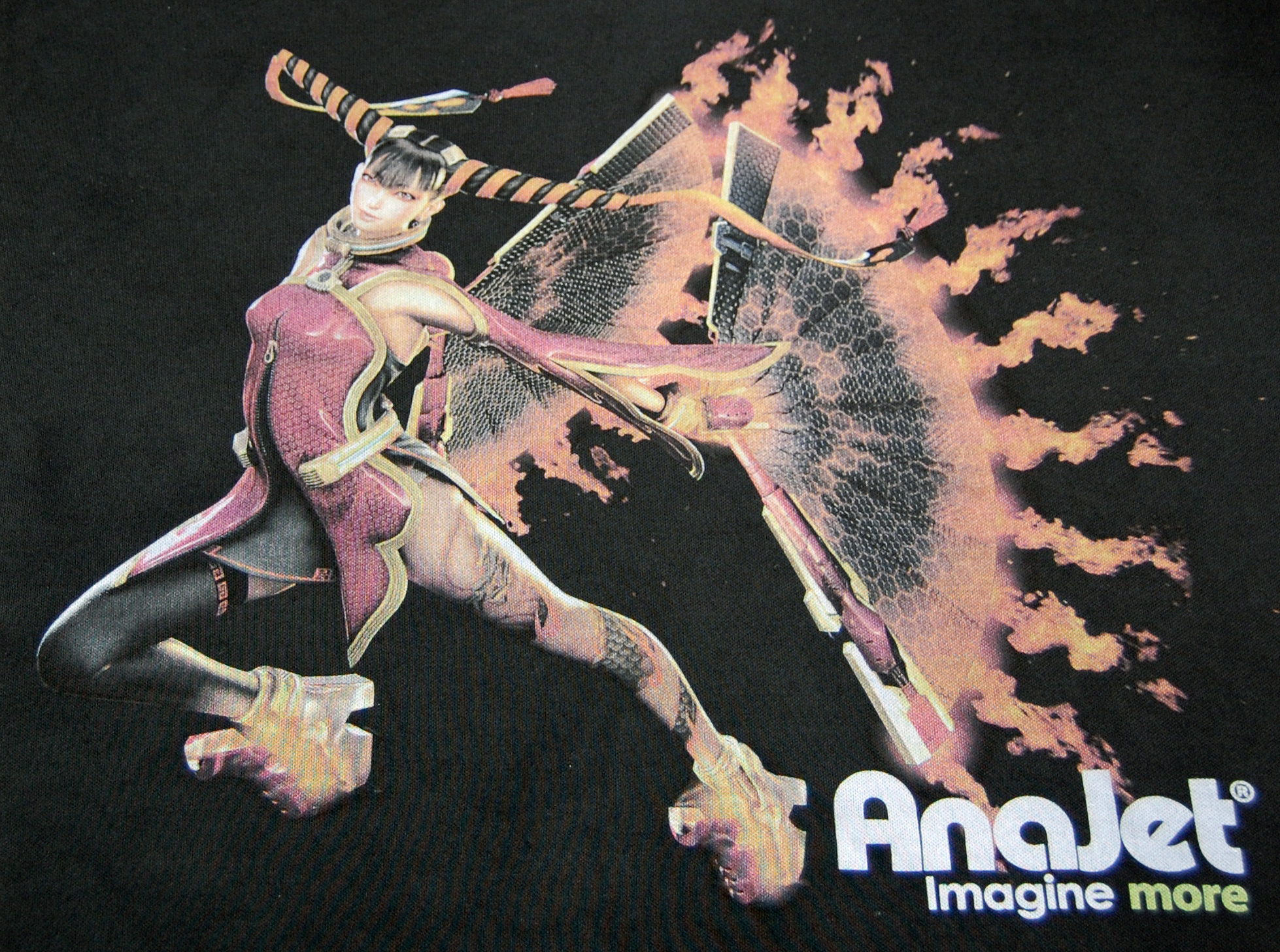

Everyone has been asking about Image Armor and we wanted to start bringing you some informative articles on using Image Armor.The current formula on the market is Image Armor Dark Shirt Formula. It sounds like it would only be good for use on dark colored shirts, right? Wrong.The image to […]

We here at Image Armor are constantly trying to improve our products, bring new products to our customers, and help our customers understand the various aspects of pretreating that are often misunderstood.In this article we are going to take a look at the wash fastness of Image Armor and the […]

We wanted to thank EVERYONE who has tried Image Armor and who have come back to us with glowing reports on how it has helped them increase their effectiveness in Direct to Garment white ink printing. From making it easier to apply to a garment and taking the guess work […]

The Holy Grail In the world of DTG white ink printing, 100% dark polyesters seem to be the Holy Grail. If only we could….In reality, polyester printing is a lot different than printing 100% cotton shirts. Most of the inks on the market today are designed to work with organic, […]

We have been asked over and over why Image Armor is so much better than the other pretreatments currently on the market. To answer this question would take an entire book to explain how we created a truly market changing pretreatment. It is like nothing else on the market. Those […]